How Vacuum Impregnation Enables Lightweighting

Recent decades have seen a surge in the use of aluminum castings in car manufacturing. Aluminum has been a critical material in car manufacturing since the beginning. The first sports car featuring an aluminum body was unveiled at the Berlin International Motor Show in 1899. Carl Benz developed the first engine with aluminum parts two […]

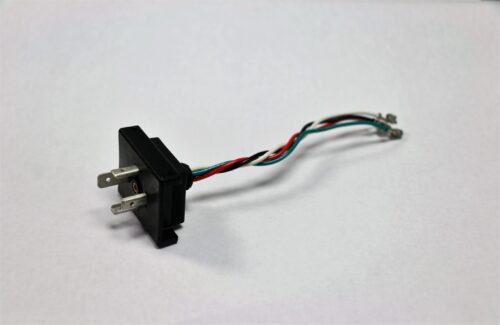

Case Study: Sealing Electronic Leak Paths with Vacuum Impregnation

Modern vehicles contain hundreds of electric control units (ECUs). These control functions that range from operation of the engine to keyless entry.

Useful Lessons from Henry Ford on Modernizing Equipment

As manufacturing equipment ages, the maintenance and repair (MRO) of the equipment increases while the Overall Equipment Effectiveness (OEE) decreases. Given this, companies must decide while bidding on new projects: “Use the aged equipment and invest in MRO while accepting a lower OEE” or “Invest in new equipment using the latest technology and generate a […]

Three Ways Recoverable Vacuum Impregnation Sealants Contribute to Environmental Sustainability

As consumer demands evolve, it’s imperative for companies to become environmentally conscious. As a result, OEMs and manufacturers who use aluminum die castings have adapted quickly, and sustainable manufacturing practices have become increasingly common.

Cost of Vacuum Impregnation

Manufacturers are constantly faced with either scrapping castings that leak or sealing the castings through vacuum impregnation. Some may perceive vacuum impregnation as a non-value added cost and assume it is less expensive to scrap die castings that leak. In this simplified yet real-world example, we will review the costs of die casting scrap compared […]

Sealing Electronics with Vacuum Impregnation vs Potting

The use of electronics in automobiles has made cars faster, safer, and more reliable. Electronics have become so prevalent that they’re practically a commodity in the same way that aluminum and steel are. As this trend continues, manufacturers need solutions that address the leak paths that occur naturally in the manufacture of these components.

Strategies for Acquiring and Financing Vacuum Impregnation Equipment

The benefits in owning and operating equipment vs. outsourcing are found in the savings of logistics, quality, and part costs. These savings serve to increase a company’s profitability. This reality holds true for vacuum impregnation equipment. But with many projects and programs competing for a limited amount of capital expenditure dollars, owning vacuum impregnation equipment […]

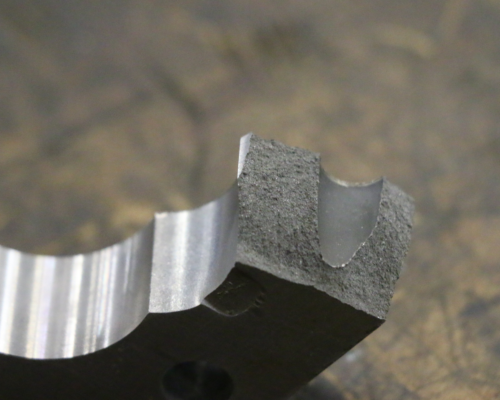

How Vacuum Impregnation Improves Powder Metal Machining

A major benefit to manufacturing with powder metal is that parts are made to near net shape. Often, machining is thus only a secondary operation for improving shape precision and surface quality.

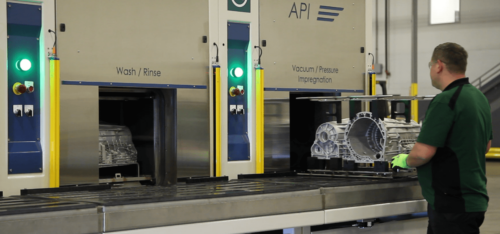

Case Study: Scalable Vacuum Impregnation Enables Supply Chain

To meet global customers’ needs, automotive Original Equipment Manufacturers (OEMs) must develop international supply chains. And when an OEM seeks to create a sustainable and efficient supply chain in a new country — regardless of whether that country has an existing manufacturing base — it is inevitably going to face challenges.

IHS Markit’s Purchasing Manufacturing Index

In its latest report, IHS Markit’s Purchasing Managers Index (PMI) offers a picture of the U.S. economy’s current state. Led by manufacturing, U.S. business activity expanded at the fastest rate in more than five years.