To meet global customers’ needs, automotive Original Equipment Manufacturers (OEMs) must develop international supply chains. And when an OEM seeks to create a sustainable and efficient supply chain in a new country — regardless of whether that country has an existing manufacturing base — it is inevitably going to face challenges.

The Challenge

One example of an OEM facing such challenges is a European company that has recently launched a new transmission case program for Italian consumers. The program is currently in a soft launch phase, during which the company must produce 155,000 parts in a year. Afterward, the forecast volumes will reach 240,000 parts per year for five years.

For this program, the OEM has decided to develop a new supply chain in Italy. Producing automobiles where its consumers are located will help the OEM improve process controls, reduce costs, and improve efficiencies. This has also meant that the Tier manufacturers would be required to supply die casting, machining, leak testing, and vacuum impregnation in Italy.

The OEM awarded the contract to manufacture the transmission case to a European Tier-One manufacturer. The manufacturer had experience in all the required processes except vacuum impregnation. Its leaders recognized that the risk of mismanagement would be high due to its lack of impregnation knowledge and Italy’s local ability. They also understood that any such mismanagement could create failures throughout the supply chain. The manufacturer needed an impregnation solution that would be easy to use, effective at sealing complex parts, and efficient as volumes increase.

The Proposed Solution

The OEM connected the manufacturer to Godfrey & Wing. While neither the OEM nor the manufacturer had used Godfrey & Wing equipment, both were aware of the success of similar programs that used the company’s vacuum impregnation technology.

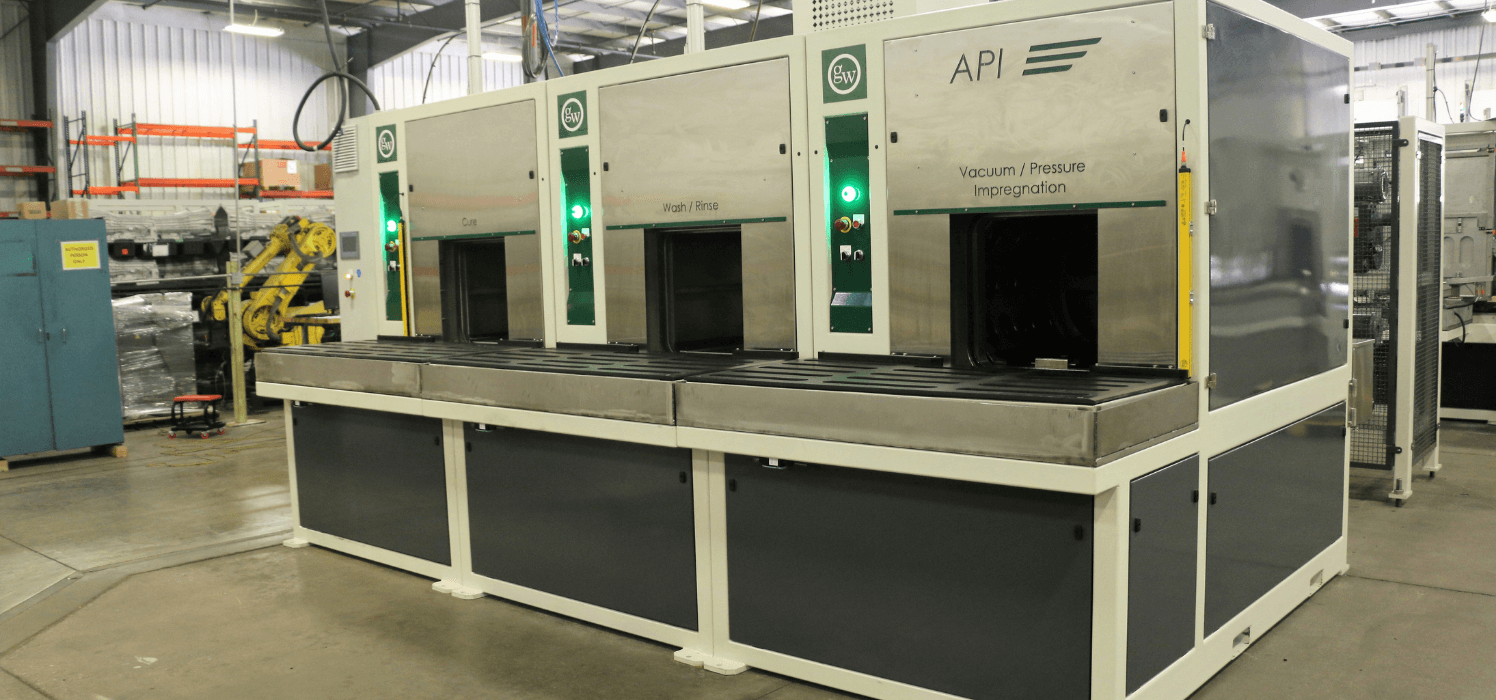

Godfrey & Wing proposed a two-part solution that would scale with the program. The first phase would occur during the soft launch. The manufacturer would train and operate on Godfrey & Wing’s Advanced Powertrain impregnation (APi) system (Image 1).

Related: Watch How the APi System Works

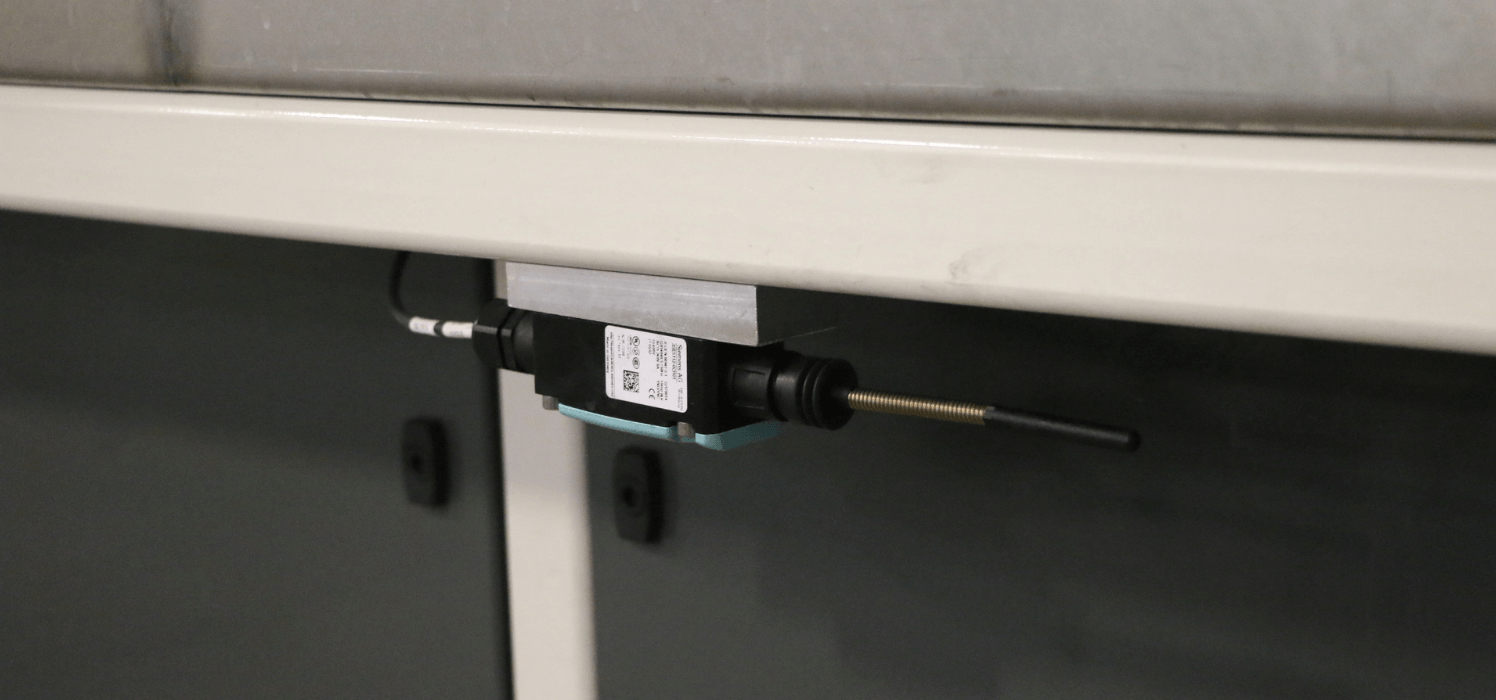

Having never operated an impregnation system, the APi would be the easiest to learn. The manufacturer would find the system safe and straightforward to use, thanks to its ergonomic design. Operators would be required to have minimal input, thanks to the system’s repeatable process. He or she would simply slide fixtures into the system, flip a switch, and let the APi do the work (Image 2).

The APi’s compact footprint of 118 square feet would fit within production without any infrastructure changes. The system would be easy to install, only requiring single point connections for electricity, water, and air.

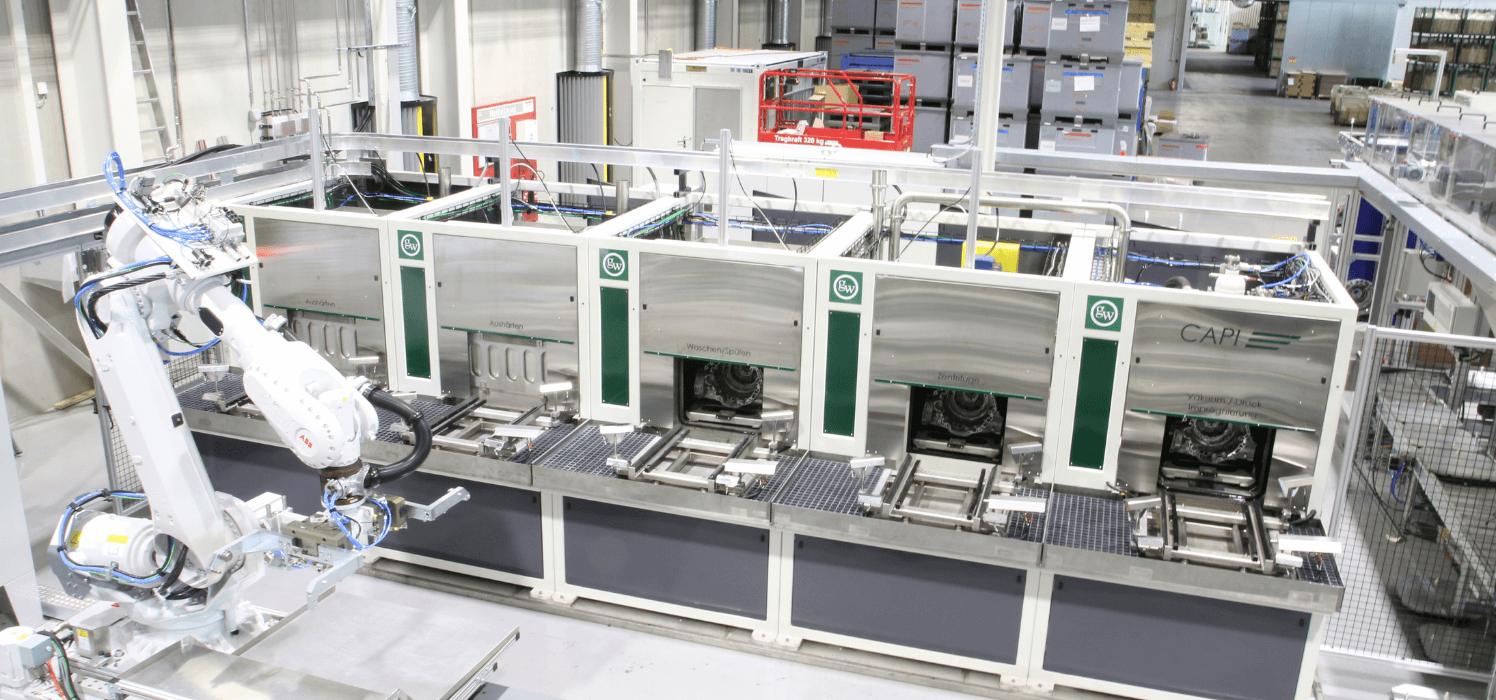

The second phase would begin once the production volumes exceed the APi’s capabilities. The manufacturer would then transition to a system serviced by a robotic arm and automated conveyors – the Continuous Advanced Powertrain impregnation (CAPi) system (Image 3).

The system’s modular design would integrate with pressure testing operations, as it’s designed to have parts fed inbound and outbound by a robot. The automation would enable the CAPi to seal parts in a short cycle time with minimal labor.

Because the CAPi is self-contained, the castings would not leave the system until meeting all the pre-determined conditions. If acceptable, then the robot would move the castings from the CAPi to the next process (Image 4).

While the proposed solution sounded viable, the manufacturer would also need to learn how to operate the systems. Godfrey & Wing would provide online and onsite support, deliver control plans, FMEAs, and other quality documents. Once installed, the manufacturer would also receive continuous training and technical support as needed. Godfrey & Wing’s systems would only operate once the manufacturer felt comfortable with them.

The Launch

After learning about the technology, the manufacturer purchased an APi for the soft launch.

While the APi was being built, the manufacturer and Godfrey & Wing held weekly, virtual meetings to discuss build progress and review all quality and operating manuals. Once completed, Godfrey & Wing installed the APi in Italy in two days. During that time, the operators and technicians applied their new skills to the machine. They processed parts, managed the sealant, and performed equipment maintenance under Godfrey & Wing’s oversight.

Since the installation, the APi has operated 24 hours per day, seven days per week. The system has addressed the manufacturer’s requirements for ease of use and effectiveness at sealing complex parts (Image 5).

With the APi’s success, the manufacturer has purchased a CAPi for phase two of this program. Once the CAPi begins operation, the APi will be used as a portable system for new programs at other locations. The manufacturer estimates that the cost to transport, install, and operate the APi will be less than outsourcing to a vacuum impregnation service provider.

Conclusion

Consumer demands will continue to evolve. As they do, OEMs and their manufacturers will continue to wrestle to meet those demands through extraordinary complex global supply chains. Empowered by Godfrey & Wing vacuum impregnation technology, this manufacturer has taken control of its porosity sealing requirements. This manufacturer replaced its vacuum impregnation inexperience with simplicity.