CFi Vacuum Impregnation System Creates Competitive Advantage

The Albert Handtmann Metallgusswerk GmbH is the largest lightweight (aluminum) foundry in Germany. When the opportunity arose for the company to cast and machine one third of the entire world production of transmission cases and clutch housings for Mercedes Benz, not just any vacuum impregnation system would work. They needed a vacuum impregnation system to […]

Have you read the latest Fundidores?

Our new Mexico vacuum impregnation plant is featured on the cover of the Fundidores April addition. If you have not read the recent Fundidores from Metal Spain, then click here to download your free copy. FYI, the magazine is both in Spanish and English. The Englsih version begins on page 28. Our Mexico service […]

Top 3 Blog Posts in 2014

As we begin a New Year, we want to share our top 3 most read blog posts of 2014. If you missed any of these articles, be sure to check them out. They include helpful information about continuous flow vacuum impregnation, the quality of an impregnation process and sealants.

Shutdown Maintenance of Impregnation Systems and Sealants

As we approach a shutdown used by many manufacturers to service plant equipment, it is important to ensure that impregnation systems and sealants be included in the shutdown maintenance program.

What Is Continuous Flow Vacuum Impregnation?

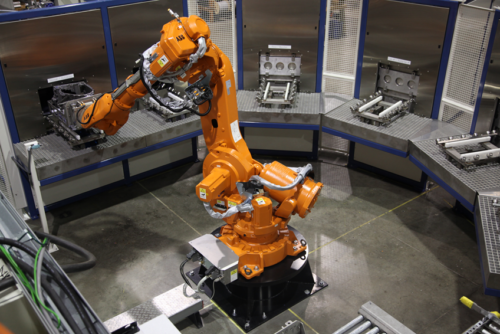

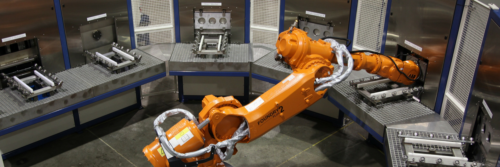

The Continuous Flow Impregnation (CFi) System is a lean, front loading vacuum impregnation system that uses a robot for part handling and transfers between modules. This impregnation system has a cycle times of less than 95 seconds. Individual part handling leads to many process improvements, such as shorter cycle times, better rinse results without risk […]

What Does It Mean When a Sealant is Qualified and Approved by MIL-I-17563C?

MIL-I-17563C is the Military Specification for cast or powder metal components. This specification is approved for use by all Departments and Agencies of the Department of Defense and “covers the requirements for impregnants suitable for use in sealing the voids found in cast or powder metal components which cause leaking of contained fluids.” To answer […]

Top 5 Blog Posts in 2013

As we begin a New Year, we want to share our top 5 blog posts of 2013. If you missed any of these articles, be sure to check them out. They include helpful information about vacuum impregnation economics, processes and sealant. How Much Does it Cost to Impregnate a Part? Or in other words, how […]

Thermal Cure and Anaerobic Sealant Applications

We often write about the different types of vacuum impregnation systems that are commonly used and how each may be best suited for use when processing a particular type of part. Once you have determined the type of system that is required, you then need to select the appropriate sealant for the system and application.

What is the lifespan of your vacuum impregnation system?

Is it more cost-effective to repair your existing vacuum impregnation equipment or to purchase a new system? There are many factors to consider when making this decision.

Don’t Hesitate to Use Vacuum Impregnation

I often meet with potential customers who are hesitant to implement a vacuum impregnation process for a variety of reasons. In this article, I will discuss the most common reasons as well as provide some explanation as to why and how a vacuum impregnation program can benefit your business.