What Is Vacuum Pressure Impregnation (VPI)?

VPI is an advanced insulation process used in the manufacturing and refurbishment of electrical components. During VPI, the component—such as a motor stator or transformer coil—is placed in a chamber where a vacuum removes air and moisture. Then, an insulating resin is introduced and forced deep into the windings and insulation system under pressure. This process ensures complete saturation and bonding, significantly improving performance and durability.

The vacuum pressure impregnation process for transformer, motor, and other components makes them better at resisting electrical breakdowns, withstanding harsh operating conditions, and performing optimally over longer periods.

Why VPI Matters for Electrical Equipment

Electrical components face harsh operating conditions—extreme heat, vibration, contamination, and mechanical stress. Standard insulation techniques often fall short, resulting in premature failures or degraded performance. VPI, on the other hand, offers several key advantages:

- Improved insulation integrity. By fully impregnating the windings, VPI eliminates voids and air pockets that can lead to partial discharges and electrical breakdowns.

- Increased mechanical strength. The solid bond between the resin and windings enhances structural integrity and resistance to vibration and thermal cycling.

- Enhanced reliability and longevity. With reduced risk of short circuits and degradation, components last longer and perform more consistently. VPI also protects electrical parts from impurities, extending their service life in a range of power distribution and industrial applications.

Godfrey & Wing: Leading the Way in VPI Solutions

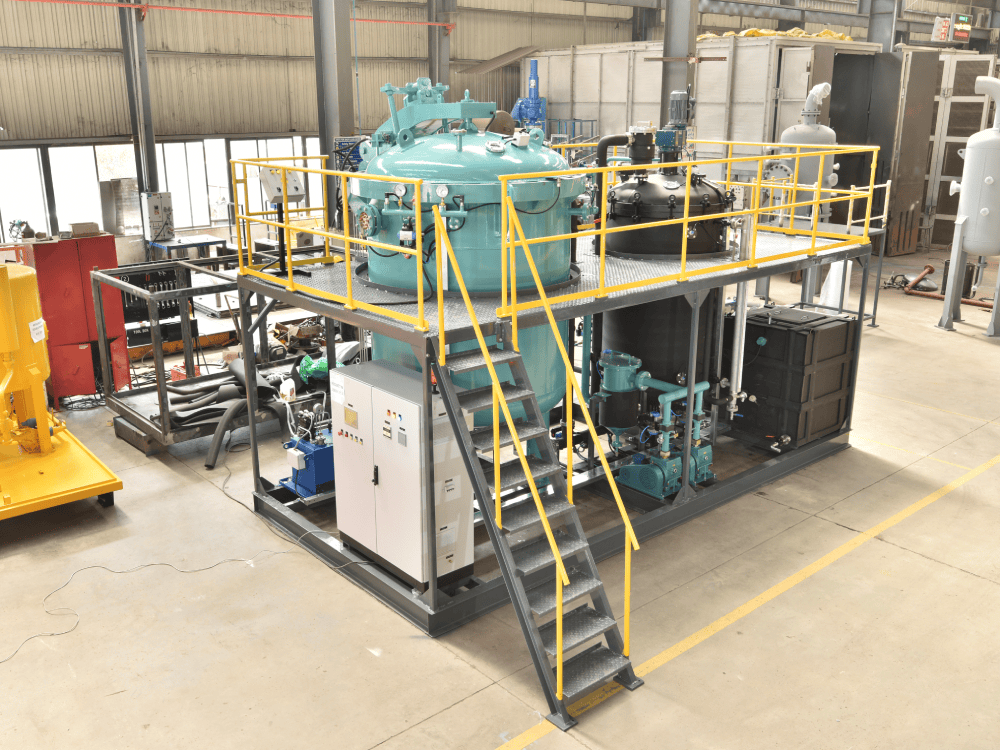

Godfrey & Wing stands at the forefront of VPI technology, delivering unmatched engineering and equipment to meet the evolving needs of OEMs and rebuilders worldwide. With over 100 VPI systems deployed globally, Godfrey & Wing has proven expertise across a wide range of industries and applications.

Here’s what sets us apart:

- Deep vacuum capability. Our systems achieve superior vacuum levels, ensuring complete resin penetration—even in the most complex winding geometries.

- Class 1, Division 1 compliance. For operations in hazardous environments, we offer Class 1, Div 1-certified systems to meet stringent safety requirements.

- Comprehensive data logging. All systems come equipped with advanced controls and data logging, allowing operators to monitor, record, and verify each step of the process for complete quality assurance and traceability.

- Scalable system sizes. From compact 12-inch chambers to massive 18-foot systems (and even larger!), Godfrey & Wing offers fully customizable solutions for any size requirement, whether you’re processing small electric motors or utility-scale transformer coils.

Custom VPI Solutions for Every Application

Every customer has unique requirements. That’s why Godfrey & Wing offers flexible, turnkey VPI systems tailored to your exact specifications. Whether you need high throughput, special resin compatibility, or automated material handling, we can engineer a system to fit your workflow and production needs.

Let’s Build Your Next-Generation VPI System

If you’re looking to increase the reliability, performance, and lifespan of your electric motors, generators, or transformers, vacuum pressure impregnation is the solution—and Godfrey & Wing is your trusted partner. We provide VPI equipment, sealants, and services to help enhance your profitability and throughput. Founded in 1948, Godfrey & Wing is the largest and longest-serving vacuum pressure impregnation equipment manufacturer in the world. Our solutions are engineered based on decades of research and real-world OEM part sealing requirements.

Contact us today to learn how our VPI systems can give your products a competitive edge.