As consumer demands evolve, it's imperative for companies to become environmentally conscious. As a result, OEMs and manufacturers who use aluminum die castings have adapted quickly, and sustainable manufacturing practices have become increasingly common.

Sustainable manufacturing aims to minimize production waste and environmental impact. This is done through designing products and adopting manufacturing processes that are more environmentally friendly. Sustainable manufacturing extends from the OEM through suppliers in both processes and materials. Included are processes such as vacuum impregnation and materials such as the sealants used in that process (Image 1).

Image 1: Sustainable manufacturing is done by designing products and processes that are environmentally friendly.

What is Vacuum Impregnation

Vacuum impregnation is a low-impact method of sealing leak paths that form during the casting process. Specifically, vacuum impregnation seals any internal, interconnecting paths of porosity that breach the casting wall and may result in product failure. The technique seals the porosity with a sealant without changing the casting's dimensional or functional characteristics.

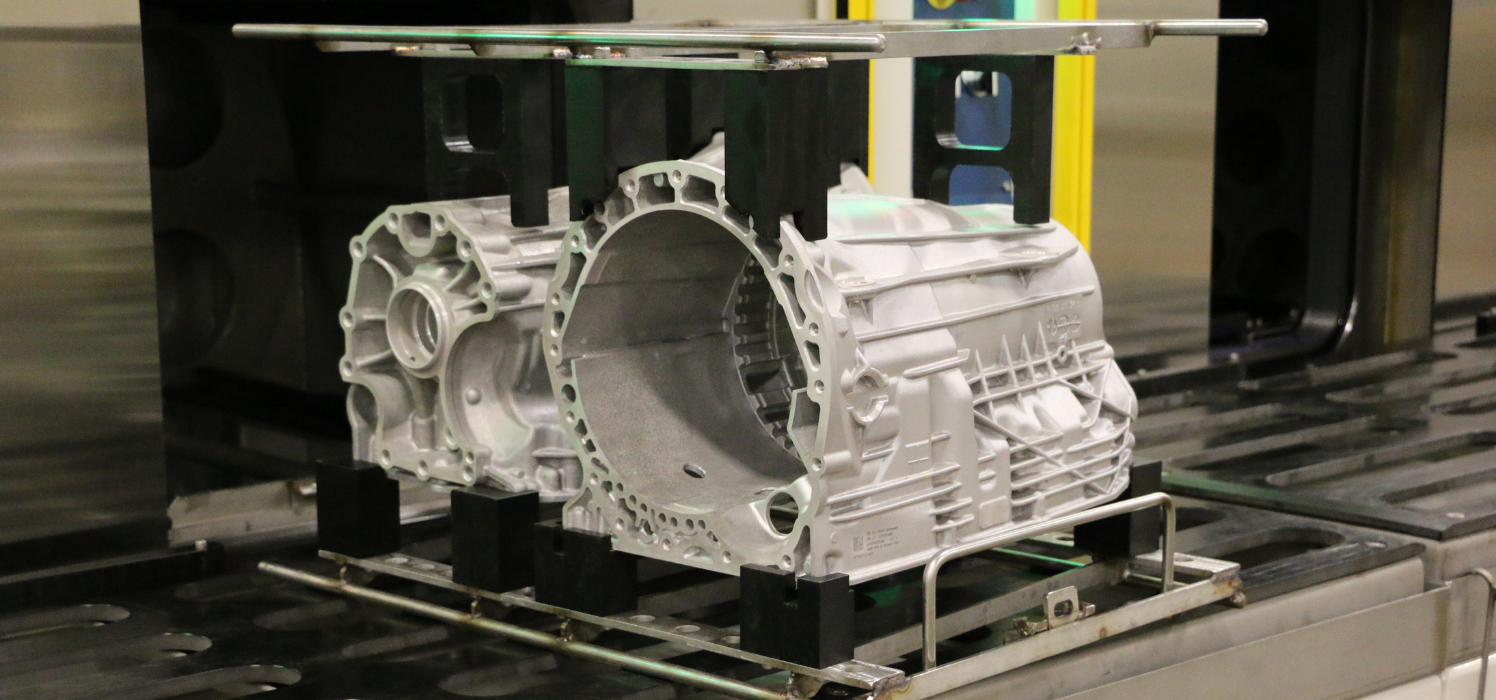

By sealing the die casting porosity, vacuum impregnation enables manufacturers to use castings that would have otherwise been scrapped. As a result, the process allows manufacturers to dramatically reduce their waste and control their resources by returning nearly 100% of parts to the production line (Image 2).

Image 2: By sealing the die casting porosity, vacuum impregnation enables manufacturers to use castings that would have otherwise been scrapped.

Benefits of Recoverable Sealants

Not only does the vacuum impregnation process contribute to environmental sustainability, but certain materials available for use with the process—specifically, a type of recoverable sealant—contributes as well. Here are the three main benefits from the most commonly used recoverable sealants.

- Recover- Recoverable sealants are automatically recovered prior to the wash and returned to the impregnation module for immediate reuse. The pure recovered sealant helps eliminate the risk of sealant contamination is eliminated.

- Reuse- Recoverable sealants remain in their original state during the impregnation process. Unlike other sealants, they do not have to be put through a costly and capital-intensive process to be reconstituted. Therefore, they can be used multiple times without additional processing to remove wash water or other contaminants.

- Reduce- Sealant consumption is reduced through efficient part handling and sealant purity. This helps ensure the part is properly sealed with no stickiness or flake contamination, whether during the first cycle or 50th cycle. Since the recoverable sealant is removed before the wash station, it does not emulsify with the wash water. Parts are cleaned in clean water and do not retain residual sealant (Image 3).

Image 3: Since the recoverable sealant is removed before the wash station, it does not emulsify with the wash water.

Conclusion

Recoverable sealants provide manufacturers with a significant advantage in sealing aluminum die casting porosity. The sealants are truly green and preserve the environment. They maximize casting recovery while decreasing risk to both operator safety and the environment.