Automated Data Collection in Vacuum Impregnation

Did we make money on that job?

Did we make money on that job?

Maquiladoras or Maquila is a word used to describe manufacturing operations in a free trade zone – typically a company that processes components imported into Mexico and then exports the components back to the company’s headquarters in another free trade country.

In the casting impregnation industry preventative maintenance is a necessity. Due to the nature of the impregnation process and the wet environment, corrosion and equipment failure can occur at a rapid rate if proper maintenance does not take place.

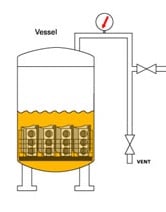

A common problem for those operating impregnation systems is sealant making its way into a vacuum pump. Sealant inside a pump (Figure 1) will lead to increased maintenance costs; premature pump rebuilds; or early pump replacement resulting from irreparable pump damage. There are multiple ways sealant can end up in the pump.

In order to maintain impregnation sealant for optimal performance, there are two vital tests that should be performed on a regular basis:

Fundamentally, there are two factors that control impregnation results – sealant quality (formulation and working condition) and vacuum (depth of vacuum). Because vacuum is such a critical factor in achieving superior results, a Godfrey & Wing representative will always recommend a DV (or DVP) process over WV when discussing the impregnation of High Value parts.

A common question asked by customers is “Why do aluminum castings discolor during vacuum impregnation?”. Aluminum parts with highly machined surfaces are more likely to be affected than those that are cast.

This year’s EUROGUSS attracted a record number of domestic and foreign visitors to Nuremberg as 8,200 people were looking for information about die casting foundries and foundry suppliers. The 383 exhibitors, of which 42% were international companies, did not just make contacts – many took orders. A wide range of products were represented from die castings, materials, furnaces, die casting machines and moulds to after treatment, quality control and research and development.

Technology, Processes & Products

Why does GW recommend the dry vacuum and pressure (DVP) process?