An Introduction to Vacuum Impregnation Equipment Safety

The beginning of the 21st century was a turning point for vacuum impregnation equipment safety, and in less than two decades there have been significant improvements in that technology, a process that had been essentially unchanged for 70 years. Developed in the 1950s, the process was adopted quickly in various industries, particularly in automotive and […]

Novelis Projects Automotive Aluminum Demand To More Than Double by 2025.

In an interview with Reuters this month, Pierre Labat, vice president of global automotive at Novelis, the world’s largest maker of rolled aluminum products, said that demand for aluminum by the automotive industry is projected to more than double over the next seven years. Labat said that aluminum is increasingly becoming the go-to metal to […]

Establishing Leak Rate Standards

A previous blog What Size of Porosity Can Vacuum Impregnation Seal? discussed that porosity occurs naturally and that the purpose vacuum impregnation is to seal leak paths created by interconnected pores. This follow up blog discusses how to define what leak paths should be sealed. It is important to understand that all materials permit leakage […]

What Size of Porosity Can Vacuum Impregnation Seal?

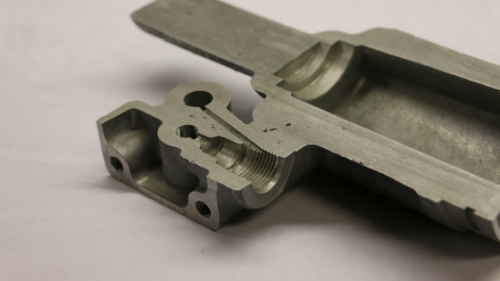

A commonly asked question is “What size of porosity can vacuum impregnation seal?” What seems like a simple, straightforward question is actually a complicated one. This blog will address the topic by describing the basics of die casting porosity, and what vacuum impregnation will seal. Porosity While some refer to porosity as a defect, it […]

Case Study: Lean Supply Chain Enabled with Vacuum Impregnation

A global automotive part manufacturing company produces aluminum engine blocks, cylinder heads, and transmission cases. The company is a Tier 1 supplier to automotive OEMs, and has facilities through the world. As such it was actively looking for opportunities to increase its efficiency and output. The Challenge This company received a contract for a new […]

Sealant Testing: What Can a Sealant Slug Tell You?

Vacuum impregnation is a process that seals porosity in metal castings. If left untreated, then the porosity creates a path for fluids and gasses to leak from the part. When performed properly, vacuum impregnation seals the porosity, but it is undetectable on the surface or in the machined features of the casting. Before vacuum impregnation […]

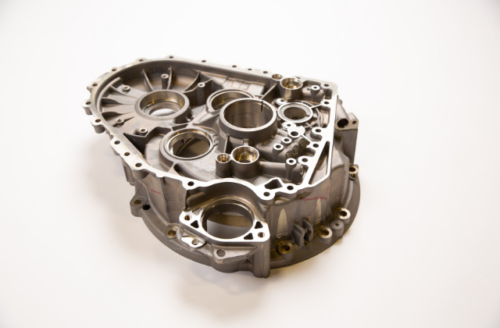

Case Study: Aluminum Casting Porosity Forces the Need for Vacuum Impregnation

One of the largest aluminum casting facilities in United States produces engine blocks and transmission cases for an automotive OEM. This facility supplies the vast majority of powertrain castings in support of the OEM’s assembly operation throughout North America. The Challenge The casting standards and aluminum characteristics forced the need for vacuum impregnation. The program was […]

Case Study: Quality Conditions Demand Impregnation Equipment

Schabmüller Automobiltechnik is a leading engineering, machining, and sub-assembly supplier to major automotive OEMs and Tier 1 suppliers. Founded in 1978, the company’s headquarters is in Großmehring Germany, and employs 850 people in four locations.

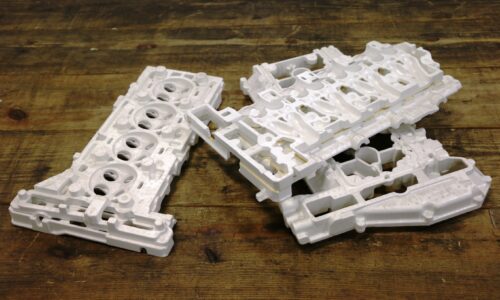

Case Study: Eliminating Shrink Porosity in Lost Foam Castings

Manufacturing castings with the lost foam process enables the foundry to produce castings with many benefits and features not available in other casting processes. This casting process is advantageous for very complex castings that would regularly require cores. It is also dimensionally accurate, maintains an excellent surface finish, requires no draft, and has not parting […]

Case Study: Vacuum Impregnation Enables Continuous Production

The Albert Handtmann Metallgusswerk GmbH is the largest lightweight (aluminum) foundry in Germany. The family-owned company has continually endeavored to improve its casting and machining processes to benefit its customers worldwide. Thus, when Daimler AG awarded Handtmann a contract to cast and machine one third of the entire worldwide production of transmission cases and clutch […]