The use of electronics in automobiles has made cars faster, safer, and more reliable. Electronics have become so prevalent that they're practically a commodity in the same way that aluminum and steel are. As this trend continues, manufacturers need solutions that address the leak paths that occur naturally in the manufacture of these components.

A leak path is any gap or void between materials in an electronic component. These gaps or voids happen during manufacturing, when different materials contract at different rates due to their natural properties. These voids may not be visible, but they can be disastrous (Image 1). Moisture or corrosive agents can seep into the leak path, causing a part to be ineffective, leading to a field failure.

Image 1: The different materials in electronics contract at different rates causing porosity. Moisture or corrosive agents can seep into the porosity, causing a part to be ineffective.

Potting and vacuum impregnation are two of the most popular methods to address leak paths in electronic components. Potting fills a part with a thermosetting plastic or silicone rubber. The vacuum impregnation process seals the internal voids with a sealant. Vacuum impregnation was first used more than 70 years ago to seal aluminum die casting porosity. While the process is still used for die casting porosity, vacuum impregnation technology has surged in the past few decades to seal electronics.

There are four main benefits of choosing vacuum impregnation over potting for sealing electronics.

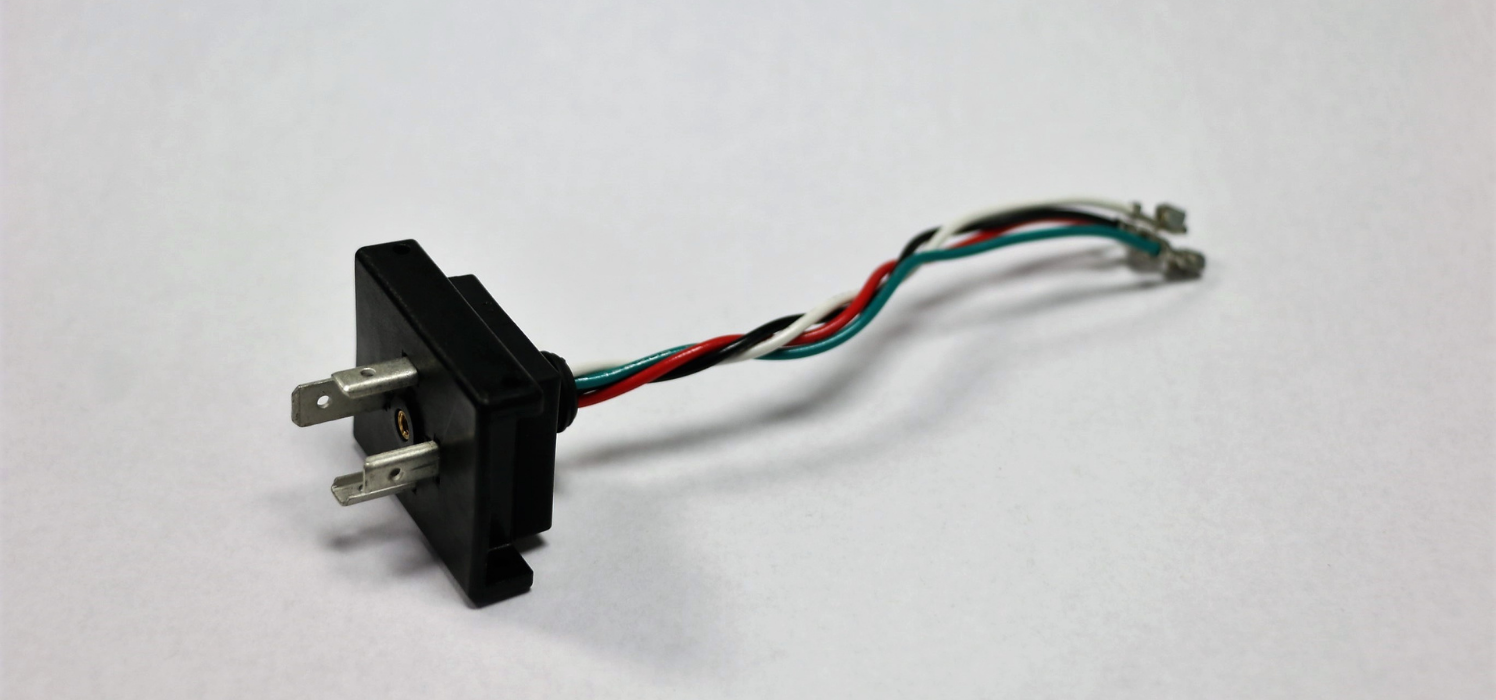

1. Vacuum impregnation seals the leak path— Vacuum impregnation seals the internal leak path, while potting fills only the leak path at the surface of the interface. Vacuum impregnation enables pressure tightness and prevents any fluids from seeping into the part (Image 2).

Image 2: The image on the left is sealed through vacuum impregnation. The part is sealed since no air bubbles appear when submerged in water. The part on the right is not sealed since air bubbles (highlighted in red) appear.

2. Vacuum impregnation enables greater design freedom—Vacuum impregnation maintains a part's dimensions, thus allowing engineers the freedom to design and make parts to net shapes. In addition, since the vacuum impregnation process occurs subsurface, an engineer does not need to incorporate dimensional allowance.

3. Vacuum impregnation costs less—The cost of vacuum impregnation equipment is less than potting equipment, which reduces capital recovery time.

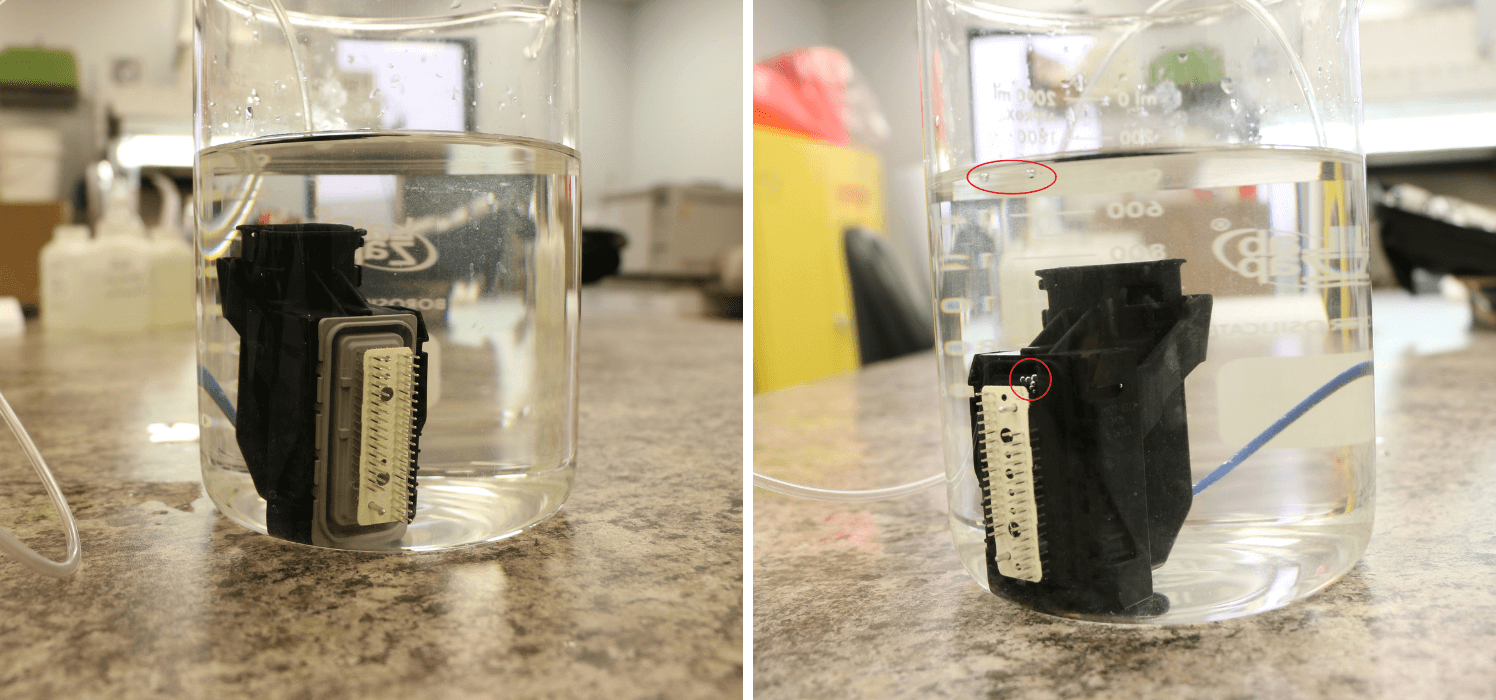

4. Vacuum impregnation provides greater throughput—Vacuum impregnation enables companies the benefit of economies of scale. The fixtures and process time allow many electronics to be sealed effectively and economically (Image 3).

Image 3: Fixtures enable a large amount of parts to be sealed at the same time. This allows companies the benefit of economies of scale.

In Summary

As the demand for electronics in automobiles continues to grow, so too will the parts' performance and leak rate requirements. The reliability and repeatability of vacuum impregnation makes it the best solution to help meet these requirements. In addition, vacuum impregnation ensures the quality of the electronics while improving profitability.