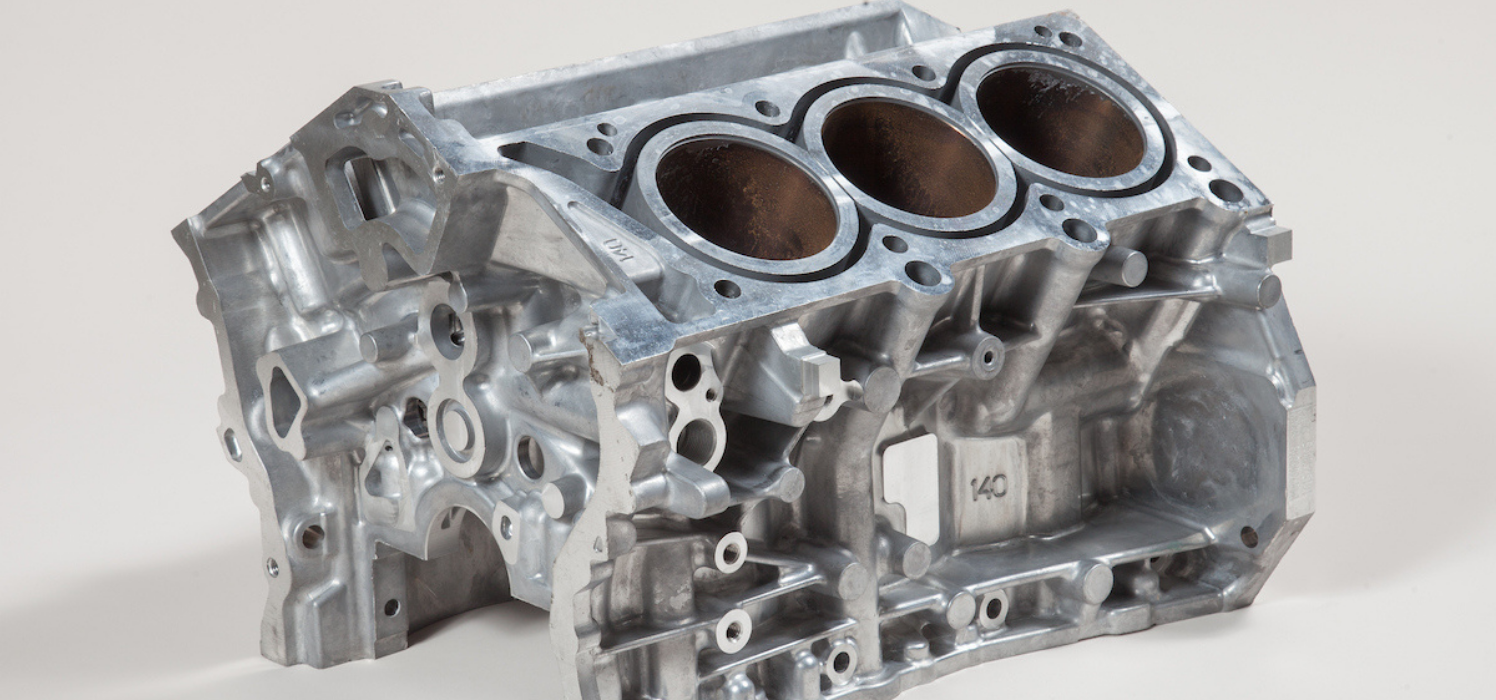

Manufacturers are constantly faced with either scrapping castings that leak or sealing the castings through vacuum impregnation. Some may perceive vacuum impregnation as a non-value added cost and assume it is less expensive to scrap die castings that leak. In this simplified yet real-world example, we will review the costs of die casting scrap compared to vacuum impregnation.

Assume an automotive OEM requires 1,000 machined cylinder blocks per day. The part is sold for $150. Of these 1,000, 3% do not pass leak test and require impregnation. In addition, assume the parts are manufactured during one shift Monday through Friday, totaling 240 days per year.

Casting Scrap Cost:

If the 30 castings are scrapped, then the cost is:

- 30 * $150 = $4,500 per day

- $4,500 per day * 240 days = $1,080,000 per year in scrap

Vacuum Impregnation Cost:

Using modern impregnation equipment will yield a recovery rate of over 96%, meaning that 29 of the 30 part are sealed. The historical cost average to ship and impregnate 30 parts per day is:

- $384 per day

- $384 * 240=$92,160 per year

Return on Investment (ROI):

- With 29 of the 30 parts sealed each day, then the company will recover $4,350 per day (29 * $150).

- With a yearly vacuum impregnation cost of $92,160, the company will have a return on its costs in 22 days ($4,350/$92,160).

- At the end of the first year, the company will have a 1,172% return ($92,160/$1,080,000).

The process is the preferred and easiest method to seal porosity.

Conclusion:

With the significantly high ROI, it is clear why the customer would choose to recover the castings. The customer will spend $92,160 to save $1,080,000 per year.Vacuum impregnation is the most cost-effective method to seal porosity.This example highlights how vacuum impregnation is a value-added cost that improves the part quality. Thus, vacuum impregnation ensures part quality while improving profitability.