Automotive manufacturers realize that being environmentally responsible and profitable are not mutually exclusive. Being environmentally responsible can achieve better growth, cost savings, improve brand recognition, and increase profitability. The environmental impact of the responsible use of resources is beneficial to everyone, and automotive manufacturers play a leading role.

Being environmentally conscious is occurring at all channels of the production process. Examples include:

Ford’s closed-loop recycling manufacturing process. The company recovers enough aluminum scraps to produce more than 37,000 new Ford 150 truck bodies each month. All while using fewer natural resources and lowering energy consumption.

Aluminum die casting manufacturers are reducing their carbon footprint with the use of green aluminum. Green aluminum is manufactured using less carbon-intensive hydropower rather than carbon-intensive fossil fuels. Making one tonne of aluminum with hydropower releases approximately two tonnes of CO2 equivalent. While making one tonne of aluminum with fossil fuels releases up to 18 tonnes of CO2 equivalent.

Manufacturers can also further reduce waste and conserve resources through vacuum impregnation.

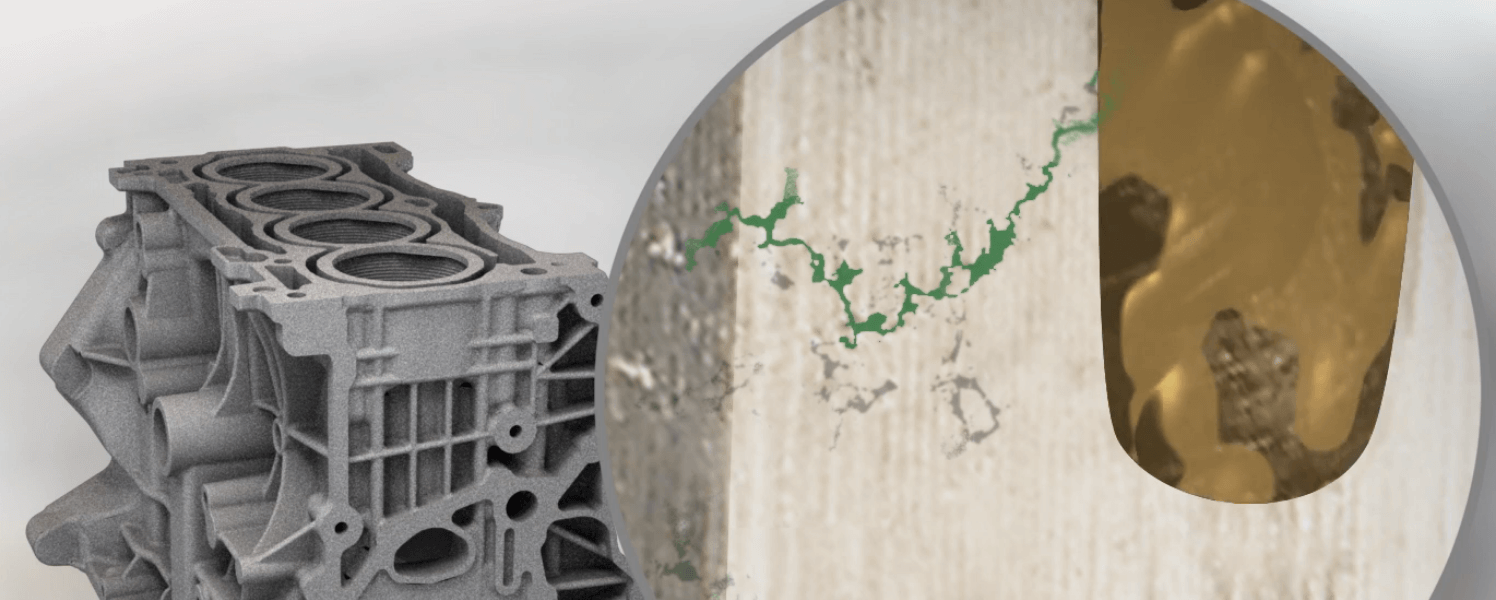

Porosity

Whether caused by shrinkage, cold shuts, inclusion, or entrapped gasses, porosity is inherent in the casting process. Interconnected porosity leads to defects, which are the leading cause of waste and scrap. This waste increases the carbon footprint of the casting process.

Vacuum Impregnation

Vacuum impregnation is a low impact method of sealing leak paths that form during the casting process. Specifically, it seals the internal, interconnecting path of porosity, which breaches the casting wall. The technique seals the porosity without changing the casting’s dimensional or functional characteristics.

Although there are many reasons vacuum impregnation enables companies to be environmentally conscious, three stand out:

- Enable Design Freedom-To make parts lighter, engineers are specifying aluminum alloys and thinner walls in critical components. Meanwhile, in order to achieve new design standards, these components have higher performance requirements and lower acceptable leak rates. These tighter requirements result in more parts being rejected and scrapped due to die casting porosity. Vacuum impregnation allows engineers to work with thinner, lightweight designs while meeting quality standards without concern over the effects of porosity. The design freedom enables engineers to design better performing and fuel-efficient vehicles.

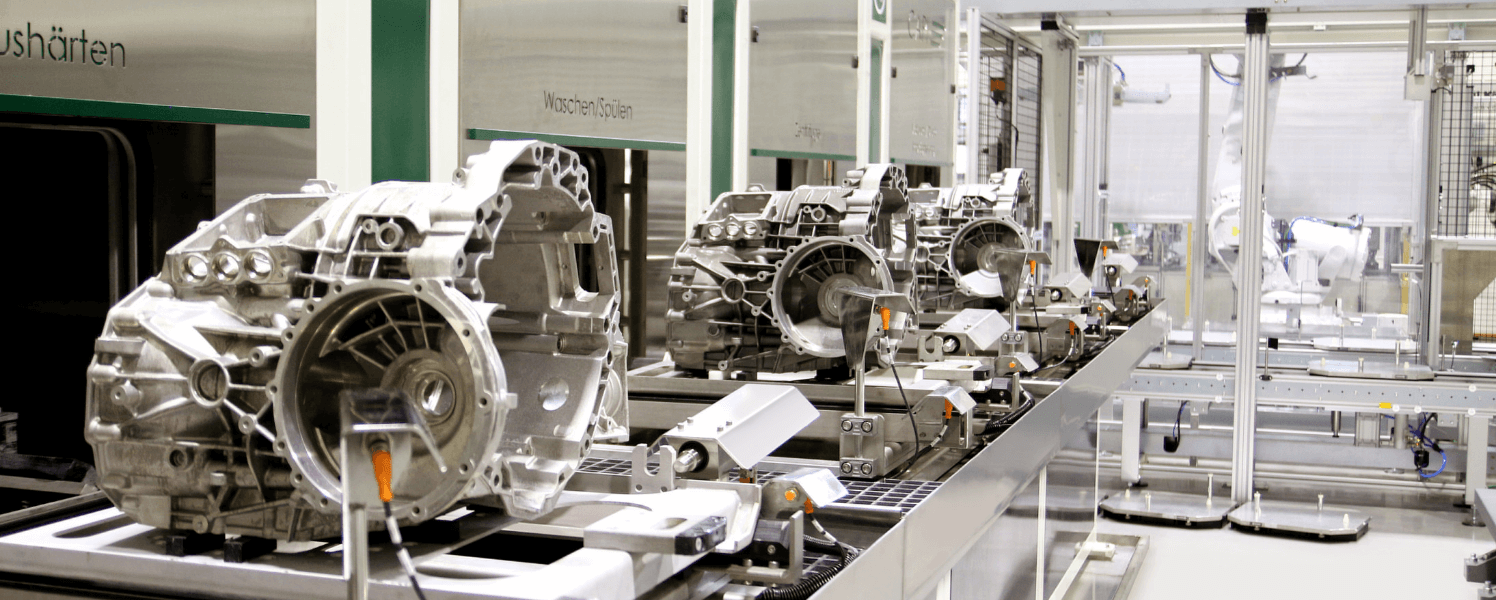

- Maximize Part Use-Porosity in castings robs manufacturers of the opportunity to move 100% of their parts into production. A 15% “fall out” of manufactured parts means that 15% more aluminum castings will be scrapped, and profits will be erased. The vacuum impregnation process enables manufacturers to use castings that would have otherwise been scrapped.

- Eliminate Melting and Re-manufacturing-Vacuum impregnation eliminates the costly melting and re-smelting of material to manufacturer replacement castings. Vacuum impregnation also removes all the carbon and waste costs associated with trimming, blasting, machining, testing, and washing of replacement parts.

These areas represent an opportunity to minimize waste, improve a company’s profitability, and positively impact the environment.

Conclusion

Automotive manufacturers must continue to aggressively eliminate waste and conserve resources to compete and grow in today’s economy. Manufacturers should look for other opportunities, through the production process, to be cleaner, safer, and make more efficient use of resources. One of those opportunities is the use of vacuum impregnation. It enables manufacturers to dramatically reduce their waste and control their resources by returning nearly 100% of parts to the production line.