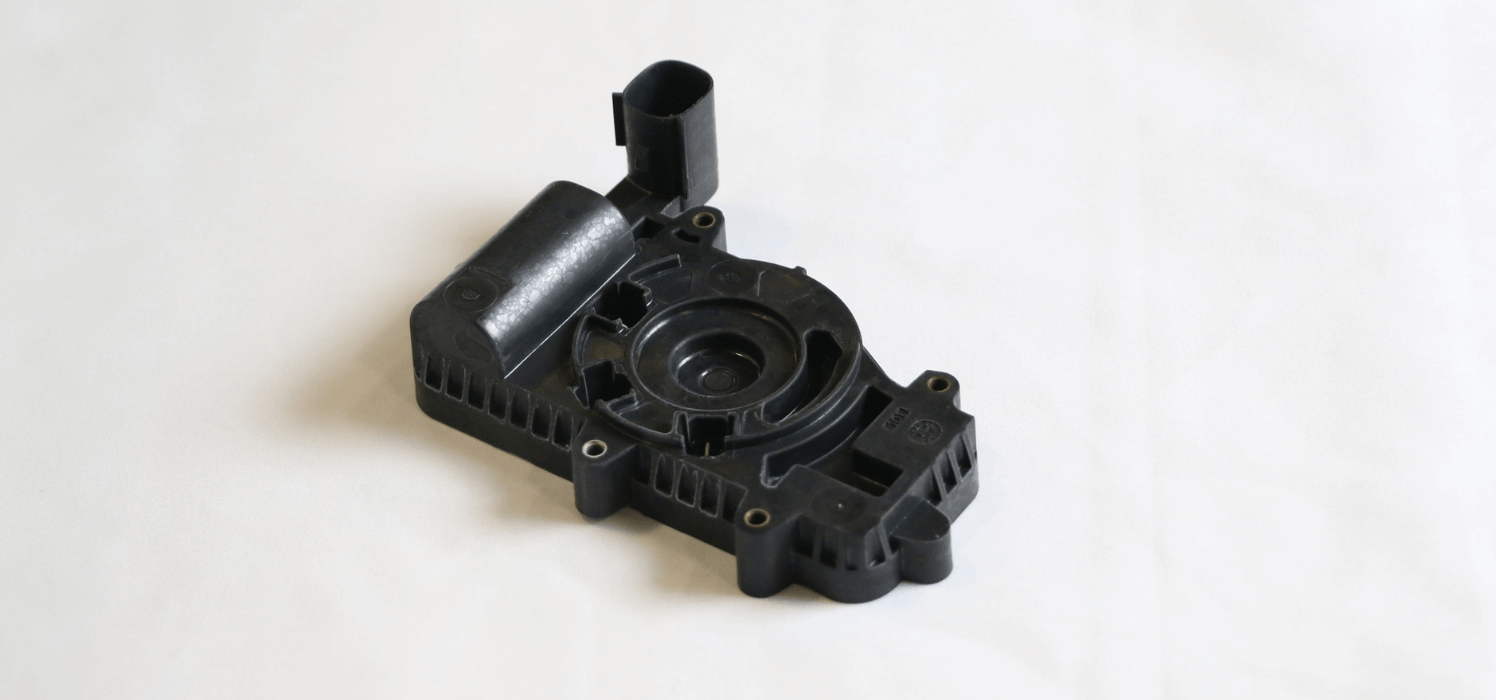

Modern vehicles contain hundreds of electric control units (ECUs). These control functions that range from operation of the engine to keyless entry. An ECU receives input from the vehicle then communicates with an actuator to perform a specific action. For example, a door lock ECU would activate an actuator to unlock or lock a door. OEMs and manufacturers are introducing more ECUs into vehicles to meet demands in features and performance.

ECUs are commonly manufactured by over-molding metal pins or wires into plastic housings. As metal and plastic expand at different rates during manufacturing, microscopic porosity is created between the materials. If this porosity is connected, a leak path will form. This leak path will create a failure point if the part needs to be pressure-tight.

This case study tells how a tier 1 automotive mechatronic manufacturer used vacuum impregnation to seal leak paths in a new, over-molded ECU.

The Challenge

The manufacturer's over-molded ECU maintains transmission pressure when the engine is stopped. The parts need to be sealed so transmission fluids do not leak into the ECU, and lubricants in the ECU do not leak into the transmission fluid. Because of this, the automotive OEM requires 100% of its parts to be sealed. In addition, the OEM requires a leak rate of zero and tight cleanliness requirements.

This tier 1 supplier previously used potting to seal similar over-molded electronics. Potting is a process of filling a complete electronic assembly with a thermosetting plastic or silicone rubber for resistance to shock and vibration and excluding moisture and corrosive agents. However, the manufacturer recognized that potting was not viable for this new part because:

- Potting would not meet the OEM's leak rate and cleanliness requirements.

- The intricate design would increase the lead time in potting, and inhibit the manufacturer from meeting the OEM's production demands.

- The high expense of potting equipment would prolong the capital recovery.

The manufacturer realized that potting would not meet this new product’s production or quality requirements. Unaware of other alternative sealing methods, the manufacturer sought advice from the OEM. Having used Godfrey & Wing to seal aluminum die castings for other automotive programs, the OEM recommended Godfrey & Wing.

Godfrey & Wing conducted a series of technical classes on how vacuum impregnation seals leak paths. Based on its new knowledge, the manufacturer realized that vacuum impregnation would be a viable solution for its challenges.

The Solution

To determine how vacuum impregnation could be most effective for the manufacturer, Godfrey & Wing conducted a Design of Experiment (DoE) using a sample of the over-molded ECU. The DoE discovered a small leak path between the over-molded plastic and metal pins. This leak path would cause transmission fluids to leak from the part, rendering the part ineffective. Multiple processes and sealants were then tested to determine the best seal rates.

Godfrey & Wing's research determined that the best process and sealant are:

- Dry Vacuum (DV) Process—Compared to the Wet Vacuum (WV) process; the DV process eliminates the resistance of sealant when the vacuum is applied.

- Elecflex 440 Sealant—Elecflex 440 has the appropriate flexibility and adhesion and conforms to the stress of multiple materials that expand and contract at different rates.

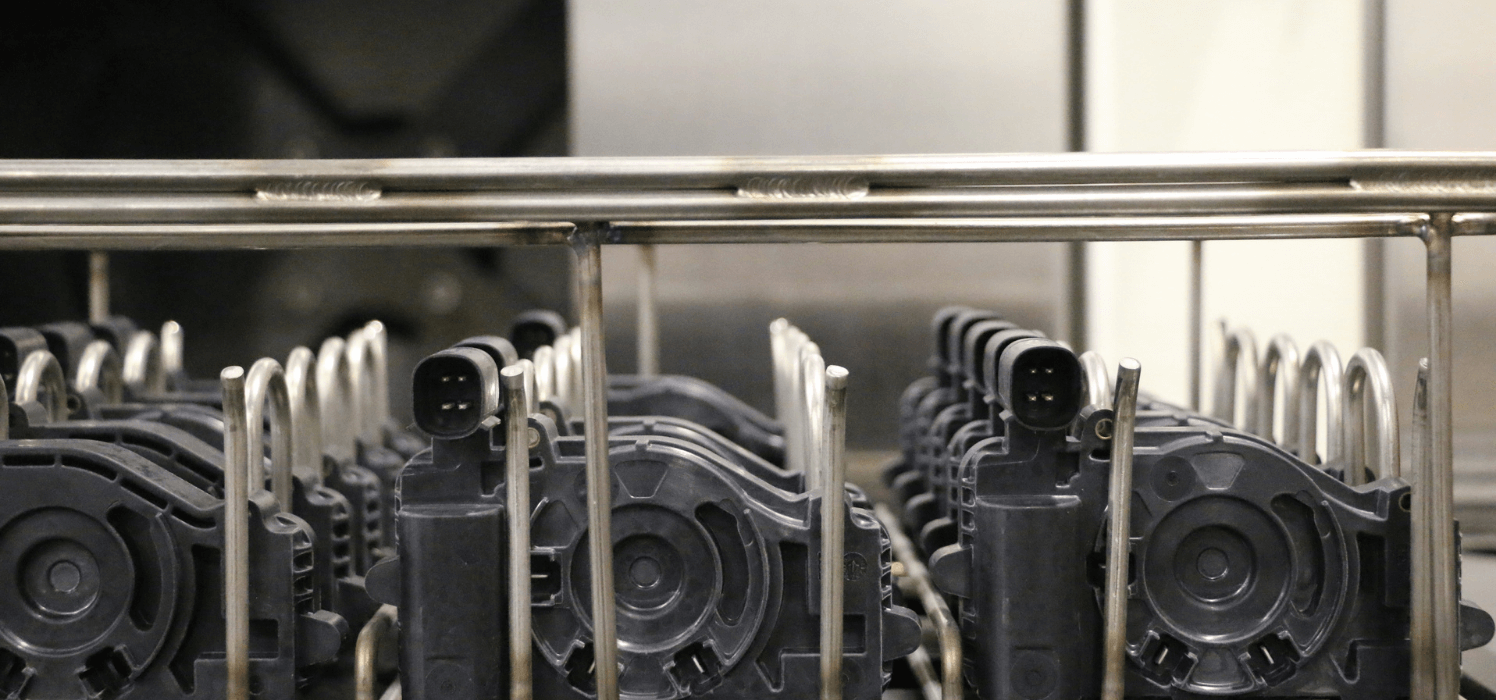

Based upon the customer's requirements and DoE, Godfrey & Wing recommended its lean, frontloading EcoSeal vacuum impregnation system.

The proposed system would include the following features:

- A centrifuge that rotates clockwise and counterclockwise to remove excess sealant. This would enable the system to recover residual sealant, reduce sealant carryover to the wash, maintain sealant purity, and preserve part cleanliness.

- Custom fixtures to allow the manufacturer to impregnate multiple parts per cycle. This approach would allow for the maximum parts per cycle, the ability to flush sealant from the blind holes, and protect critical over-molded features.

- A small footprint of 66 square feet. This would enable the EcoSeal to integrate within the production cell without infrastructure changes.

The manufacturer reviewed and approved Godfrey & Wing's proposal.

The Results

Once the system was completed, the manufacturer received onsite training at Godfrey & Wing. Then when the system was installed at the manufacturer’s facility, operators and technicians received further training on operating and maintaining the EcoSeal. Having no prior experience operating a vacuum impregnation system, the manufacturer found the EcoSeal easy to use.

The EcoSeal is making a significant impact by answering the following challenges:

- Achieve leak rate, and cleanliness requirements-The DV process pushes the Elecflex 440 sealant deep into the leak path, improving sealing efficiency. This results in a meaningful improvement in meeting the OEM's leak rate and cleanliness requirements.

- Attain production volume-The system is integrated with the customer's injection mold presses and pressure testing, allowing for continuous production flow. The system seals 300 parts per hour, over three shifts per day, five days per week.

- Lower cost per unit-The cost of the Ecoseal is approximately 66% less than a new potting system. This enables the customer a faster capital expense recovery.

In Summary

As the use of electronics in automotive manufacturing continues, so too will the demand for vacuum impregnation to seal the leak path of electronics. Through research, Godfrey & Wing's frontloading EcoSeal, DV process, and Elecflex 440 sealant, collectively, is the best and most economical option to meet the quality and production demands.