Anaerobic Sealants

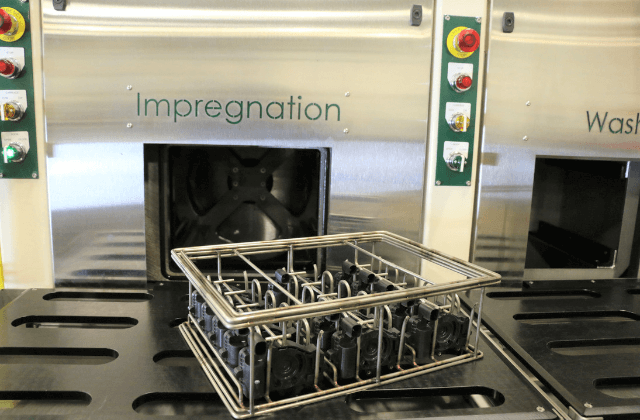

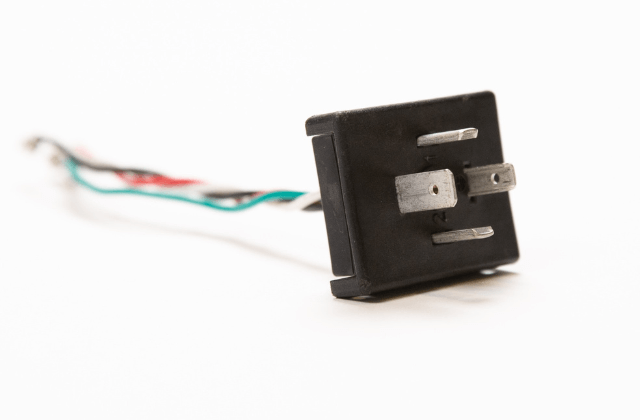

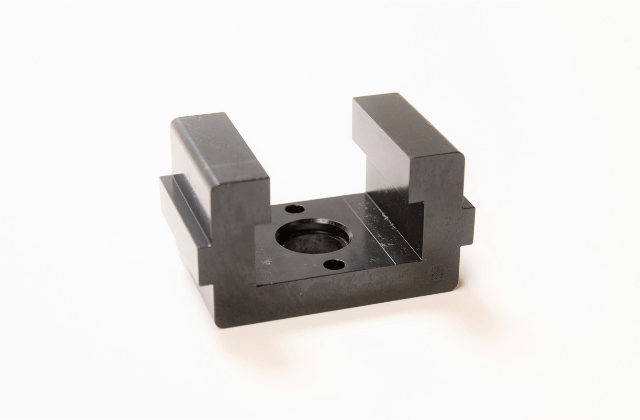

Anaerobic sealants are commonly used for powdered metal 3D printing, and overmolded electrical components. Because they cure at room temperature with no heat, they’re ideal for impregnating components with dissimilar materials that have varying coefficients of thermal expansion. These sealants are optimal for the Wet Vacuum (WV) process.

|

95-1000AC |

95-1000ACP |

Elecflex 440 |

Elecflex 330 |

ElecflexFP |

|||

|

General Purpose |

Castings | Powder Metal | Electronics | Fuel delivery components | Flame resistant | ||

|

Hardness, Shore D |

79 | 83 | 52 | 70 | 50 | ||

|

Density |

1.21 gms/cc @ 72°F (22°C) | 1.22 gms/cc @ 72°F (22°C) | 1.06 gms/cc @ 72°F (22°C) | n/a | n/a | ||

|

Coefficient of Thermal Expansion |

2.5 x10-4 in/in/in °C |

2.8 x10-4 in/in/in °C |

1.52x10-4 in/in/in °C |

2.5 x10-4 in/in/in °C |

n/a |

||

|

Compressive Strength |

9,668 psi | 10,275 psi | 3,339 psi | n/a | n/a | ||

|

Compressive Modulus |

38,672 psi | 146,786 psi | 5,757 psi | n/a | n/a | ||

|

Operating Temperature |

-40°F to 401°F (-40°C to 205°C) | -40°F to 401°F (-40°C to 205°C) | n/a | n/a | -51°F to 401°F (-46°C to 205°C) |

Fully Recoverable

All Godfrey & Wing sealants are recoverable. Their use improves part sealing, maintains purity of the impregnation process and eliminates risk of sealant contamination.

Use of recoverable sealants allows for ease of use, longer pot life and stable properties

Cost Effective

Recoverable sealants remain pure in its original formulation throughout the manufacturing process. Retaining and using pure sealant means no additives or excessive maintenance is needed. Resulting in the highest possible part quality while reducing cost and maintenance time.

Approved by OEMs Worldwide

Godfrey & Wing’s anaerobic sealants are approved by OEMs worldwide. The world’s leading manufacturers trust that Godfrey & Wing’s sealants are repeatable and sustainable.