What is Vacuum Impregnation

What is Vacuum Impregnation?

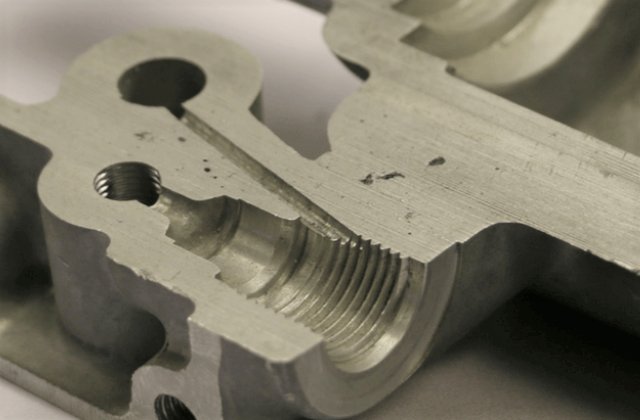

Vacuum impregnation seals porosity and leak paths that form during the casting

or molding process.

The process stops porosity and allows manufacturers to use

parts that would otherwise be scrapped.

Vacuum impregnation is the preferred method to seal porosity to prevent fluids or

gas from leaking under pressure.

What Causes Porosity?

The casting and molding processes are very sophisticated, but they still result in natural defects of porosity.

When the raw materials are liquefied and injected into a mold, the process creates gas bubbles that get trapped as the material solidifies.

These gas bubbles create air pockets, folds and inclusions. Depending on their size and placement within the part, this porosity can create leak paths that allow fluids and gases to escape under pressure.

Ensure Quality and the Bottom Line

Godfrey & Wing vacuum impregnation technology is engineered to overcome the porosity challenges. They enable manufacturers to meet OEM requirements, ensure the quality of their components, and the integrity of their bottom line.

As the need to seal leak paths evolves, so will Godfrey & Wing's technology. We are continuously creating processes to help manufacturers of an even wider range of materials overcome the porosity challenge.