Godfrey & Wing has installed an automated Continuous Flow Vacuum Impregnation System (CFi) for Schabmüller Automobiltechnik GmbH. Schabmüller will use the equipment to impregnate cylinder head covers for the V6 Audi engine in Ingolstadt Germany.

Schabmüller Automobiltechnik is a leading mechanical engineering, machining, and assembly supplier to major automotive OEMs and Tier 1 suppliers. Founded in 1978, the company’s headquarters is in Germany with 850 employees in four locations.

The contract is a result of Audi’s requirement for 100% porosity sealing of the cylinder head covers. By integrating the CFi with in-house production, Schabmüller could meet the production cost, volume and quality specifications without concern. The CFi system includes the most advanced porosity sealing technology available with the capability of sealing 600,000 units per year.

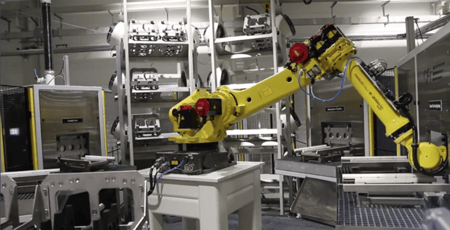

The CFI’s modular design allowed Schabmuller to integrate vacuum impregnation directly into the head cover manufacturing line. The robotic automation provides repeatable processing with minimal maintenance and eliminates part contamination and handling damage. The CFi is fully self-contained for quality with the robot and PLC working together to ensure that parts met all of the pre-determined process parameters.

This agreement significantly extends Godfrey & Wing’s relationship with Schabmüller. The contract not only includes Godfrey & Wing’s equipment technology but an ongoing supply of Godfrey & Wing’s high performance impregnation sealant. The sealant is approved and certified by the U.S. Department of Defense and specified by automotive OEMs worldwide.

Next Steps:

- Talk to us about what services and equipment are right to you.

- Learn more about our vacuum impregnation equipment.

- Understand porosity and vacuum impregnation by downloading our handbook.