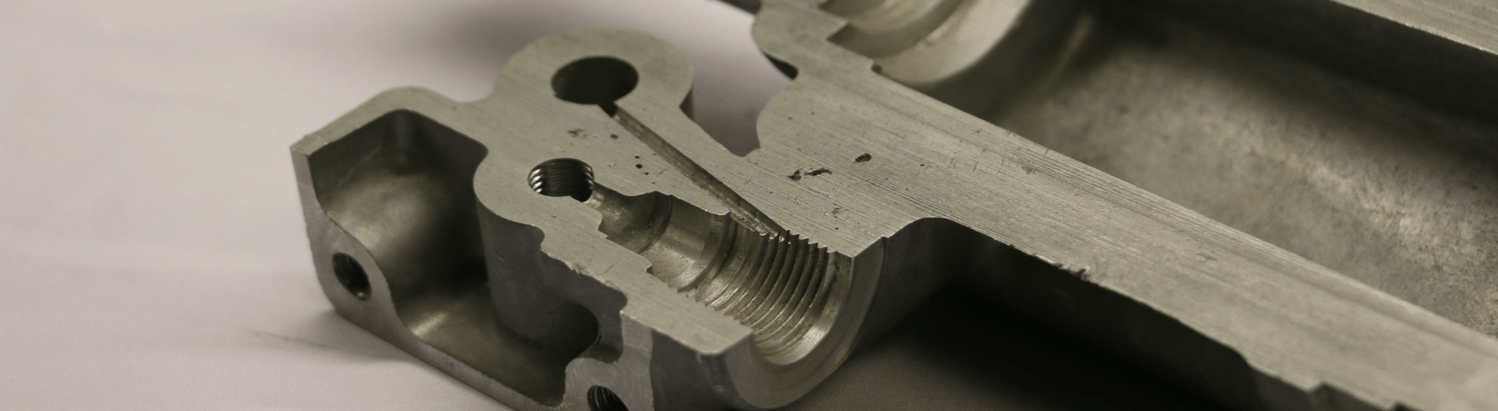

The phrase aluminum die casting porosity is used extensively when talking about any void in an aluminum casting, but it does not describe the actual problem. It can take many different shapes and forms, but it is often described just as “porosity”. When analyzing a casting’s porosity, it is important to describe specifics like size, shape, location, and frequency (Image 1). Since porosity is within the casting’s walls, the best way to analyze it is through Nondestructive Testing.

Image 1: Die casting porosity can take many different shapes and forms. The best way to analyze it is through Nondestructive Testing.

What is Nondestructive Testing?

Nondestructive Testing (NDT) is the process of inspecting and evaluating components for discontinuities or differences in characteristics without destroying the part. Bottom line, after NDT the part can still be used in production.

Radiographic Inspection

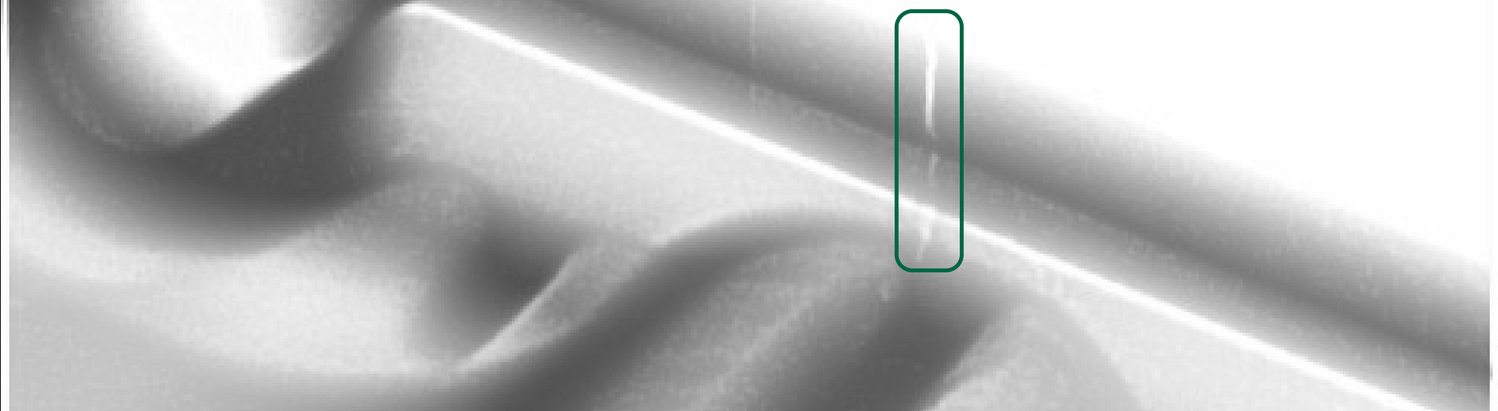

While there are various types of NDT testing the most effective for porosity is radiographic inspection (X-Ray). This is because porosity is within the casting walls. In this method, the casting is exposed to radiation from an x-ray tube. Dense material withstands the radiation penetration, giving these areas a darker appearance. Less dense materials, such as porosity, allow more penetration and are shown as a lighter appearance (Image 1).

In addition, X-Ray testing serves as a permanent record to the casting’s porosity. The testing allows for tractability throughout the manufacturing process.

Image 1: The porosity (highlighted in green) is shown in a lighter appearance, while the rest of the casting has a darker appearance.

Four Reasons to Inspect Casting Porosity with X-Ray

From the design stage through production, there are three main reasons why X-Ray inspection is done:

1. Diagnostics

The term porosity alone does not determine if it is a defect. Porosity only causes casting defects when it creates a leak path or structural problem in the part. X-Ray identifies if the porosity causes the defect by showing the porosity’s type, location, and frequency.

2. Determine Repair Criteria

X-Ray allows manufacturers to define acceptance rates. The customer can then integrate acceptable parts into production, and seal the porosity of rejected parts though vacuum impregnation.

3. Prohibit Contamination of Noncompliant Parts

X-Ray allows the manufacturer to remove non-conforming parts from production. This prevents the risk of failure downstream in the production cycle.

4. Preventative Tool

Porosity in castings is inevitable, but it can be minimized. X-Ray can be used during the R&D stages to help part and tooling design to reduce porosity as much as possible.

In Summary

Porosity is inherent in casting manufacturing. With OEM specifications becoming ever more rigorous, this porosity often leads to greater waste, increased costs, inhibited capacity and delayed production. Because porosity is an internal defect, Nondestructive X-Ray is the best inspection method to measure casting porosity while still being able to use the parts in production. Nondestructive X-Ray testing enables companies to identify areas of concern before porosity causes defective parts.