As manufacturing equipment ages, the Overall Equipment Effectiveness (OEE) decreases. A company that fails to invest in equipment, will not be able to meet demand or produce a quality product, thus potentially losing its competitive edge. Companies who want to succeed in this landscape are identifying equipment investment opportunities to keep production moving and while producing a quality product.

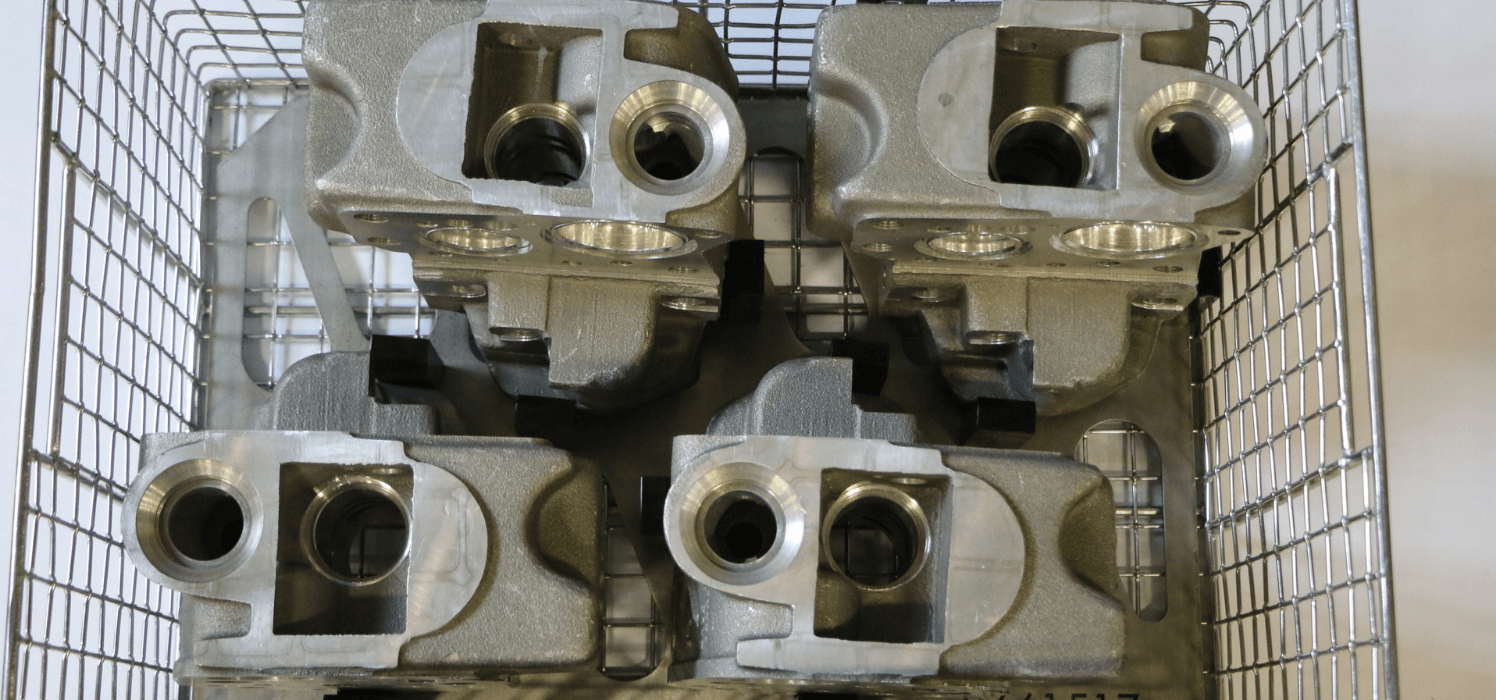

One example of such a company is a global air brake and train control system manufacturer. The manufacturer had a surge in production, and its in-house vacuum impregnation line could not meet the production demands. The impregnation system was in the company’s Mexico facility. This facility cast, machines, impregnates, assembles, and tests the aluminum castings before shipping to its OEM customers.

The Challenge

The manufacturer was using a batch impregnation system with a thermal-cure sealant. The system aggregated castings after machining and processed them in large batches. After processing, the castings moved to washing.

After considerable research, the manufacturer determined that their batch system caused the following challenges.

- Poor Recovery- The batch system’s historical average First Time Through (FTT) was 85% recovery.

- Wash Contamination– The batch system lacked a centrifuge, which caused a significant amount of sealant to be dragged into the wash. The contaminated water affected the system’s ability to wash sealant from casting surfaces.

- Water Use– Due to this contamination, the manufacturer continuously replaced its wash water. Strict water regulations in Mexico forced the manufacturer to dispose of this water by collecting it in totes and sending it to a water treatment facility. The manufacturer used approximately 600 gallons of water per day.

- Ineffective Process Flow– The system was permanently positioned outside the flow of the production line, requiring the operators to move parts to and from the batch system. This increased overall production cycle time and increased the risk of handling damage.

To meet the production surge, the company’s leaders decided to replace this equipment with a modern, lean impregnation system.

The Solution

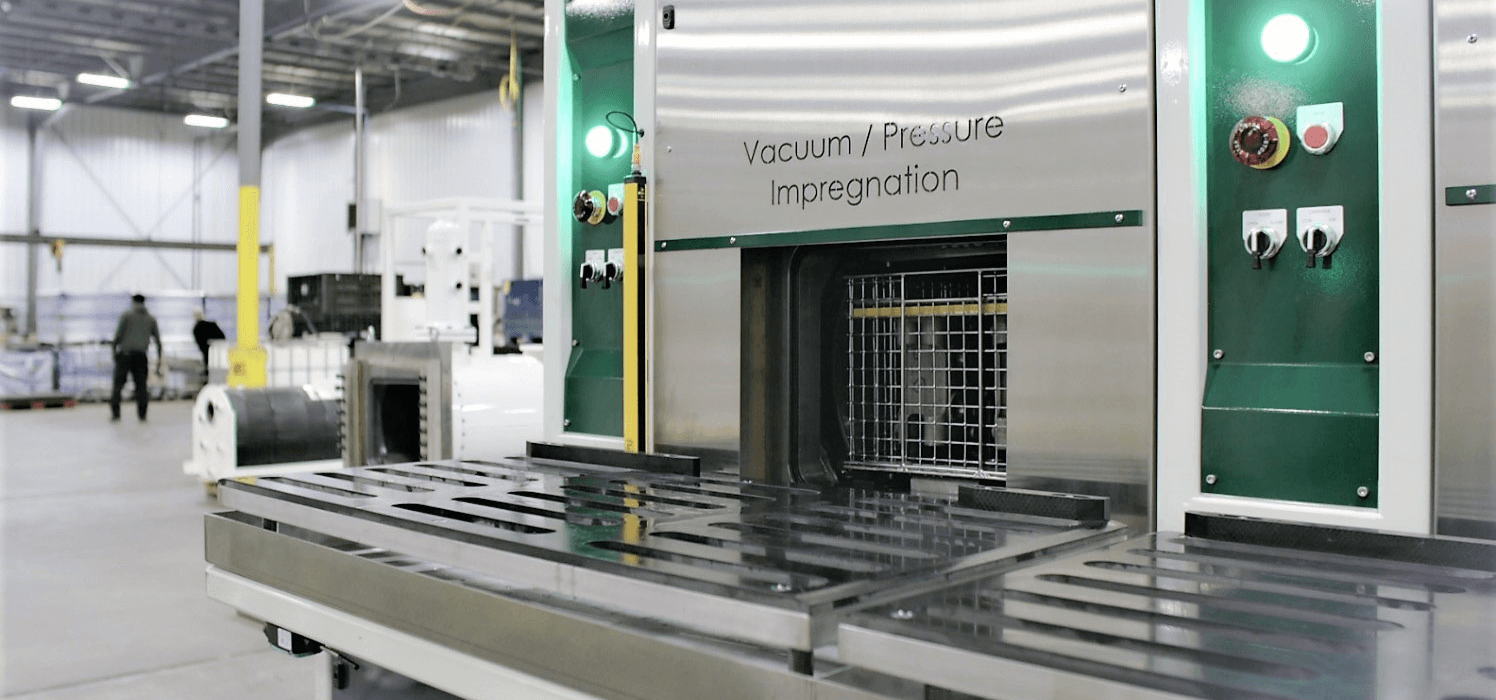

Based upon these requirements, Godfrey & Wing recommended the HVLV vacuum impregnation system. This system was engineered to address all the customer’s challenges.

The HVLV uses the patented Dry Vacuum and Pressure (DVP) process. Demonstrated to be the most effective vacuum impregnation process in the world, DVP incorporates a fast, deep vacuum to evacuate air from a casting’s porosity. The system applies high pressure to allow the sealant to thoroughly penetrate deep in the casting walls.

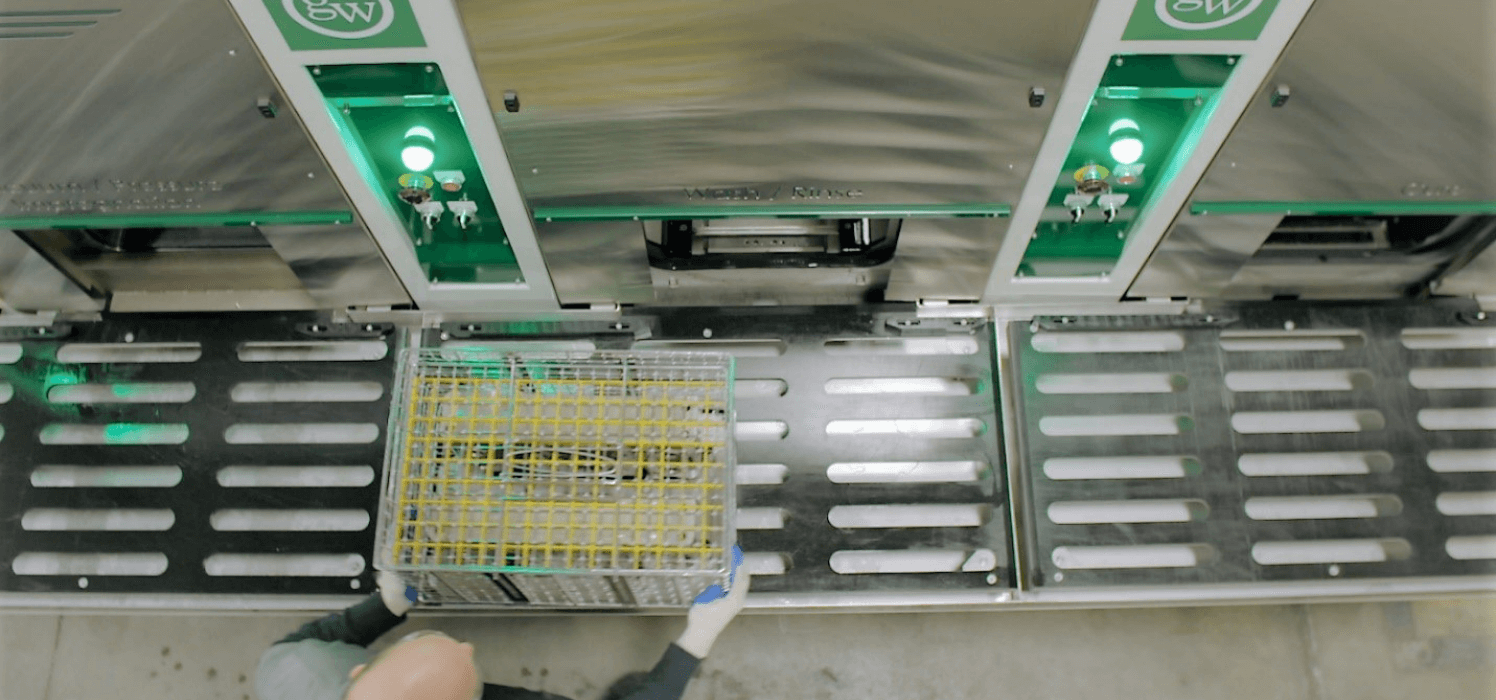

Custom-designed fixtures hold the castings in place. This maximizes the number of castings that can be processed per cycle, helps ensure sealant is flushed from blind holes, and protects critical machined features. The HVLV’s ergonomics allow the operator to easily slide the fixture on the platform to each module, enabling faster processing than a batch system.

After sealant penetration, the fixture is processed through a centrifuge to recover unused sealant. The sealant is returned to the sealant reservoir for use in subsequent cycles. Conserving unused sealant prior to the wash enables the wash water to remain pure. This allows the wash water to fully clean the part, eliminating the risk of contamination.

At a demonstration of the HVLV system at Godfrey & Wing’s Mexico facility, the customer had an opportunity to process parts themselves. The customer found the system simple, safe, and faster to use compared to their current batch system. The HVLV’s FTT rate was exceedingly higher than the customer’s batch system.

They were also able to see firsthand how flexible the system really is. The modular footprint of 96 sq. feet, and single point connections for electricity, water and air allow the customer to easily integrate the system into their production. The system could fit into the customer’s existing production line.

After the demonstration, the company decided to purchase an HVLV.

The Results

The HVLV was installed, operators and maintenance were trained, and the system was running production in under a month. Since then, the HVLV is addressing all the company’s challenges.

- Improved Recovery– Scrap from porosity has been virtually eradicated with the HVLV delivering a FTT rate of over 99%.

- Eliminate Contamination-The system’s centrifuge conserves excess sealant, and eliminates it from being dragged into the wash.

- Conserve Water-The manufacturer has reduced water use by 40%, and now uses 360 gallons per day.

- Effective Process Flow-The system is integrated with leak testing. The fix on fail parts are delivered from leak testing via a conveyor belt, then delivered to the next operation via an outbound conveyor belt.

With the success of this new vacuum impregnation system, the company is projecting the capital expense recovery to be 12 months.

In Summary

This company realized that as technology advancement are made, equipment investment is necessary to meet the ever-changing requirements. Godfrey & Wing’s HVLV system is the best and most economical option for the customer’s needs. The system creates a competitive advantage by operating at the highest OEE possible.