In some die casting applications, components must also be pressure-tight to hold pressurized fluid or gases. Companies use the vacuum impregnation process to meet these requirements by sealing the internal leak paths without impacting any other features of the casting. A commonly asked question is in addition to leak paths, can vacuum impregnation seal die casting cracks? This video answers this question with easy to follow visuals.

Video Transcript

Hola, y buen dia todos. Welcome to another edition of “Casting Call with Johnny Impreg.” I’m your host Johnny Impreg and in this episode we’re gonna get into the question of “Can Vacuum Impregnation Seal Cracks?” I’d like to rephrase that a little bit and say “Should Vacuum Impregnation Be Used to Seal Cracks?” I’ll start out with the answer is, “No, you should never use vacuum impregnation to seal a crack.”

Let’s Get Into the Science

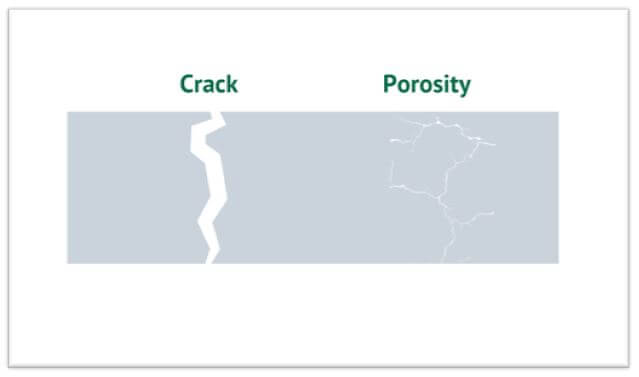

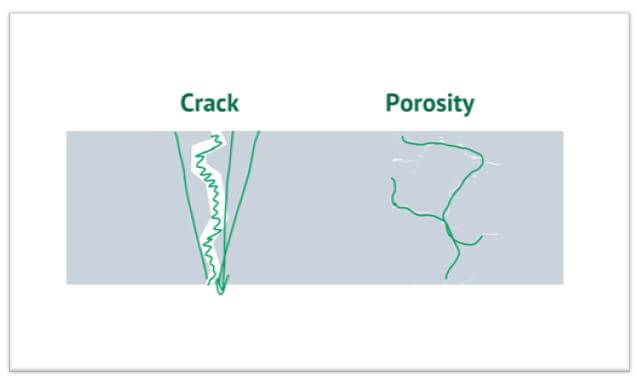

Now let’s get into the science a little bit, I’ll explain why I say that. Now, everybody’s familiar with porosity, and that’s kind of formed during the solidification process, is either shrink porosity or gas porosity. And when that forms, when the casting freezes, that’s static. It’s never going to move so that when we fill the casting porosity with sealant, that’s never going to open up again. That leak path is sealed and the sealant will survive as long as the casting. Now, if you take a look at a crack, on the other hand, a crack forms post-solidification, typically in the injection. Sometimes in handling after the casting is ejected. But, the crack is not static and can move.

Impregnating Cracks vs. Impregnating Porosity

And what will happen is sealant will actually seal it and it may pass leak tests. But then when you go to assemble it and torque it down for assembly, or worse yet, when it gets out in the field, the crack can propagate and open up again, and then that will open up the leak path. So it will fail later on.

And cracks can be a real problem with castings because it can be difficult to detect. You can actually have a crack that’s so slight it will pass leak test to be an impregnation candidate. You impregnate it and it will seal for a passing leak test, then it gets out in the field and it leaks. Oftentimes folks will jump to the conclusion that impregnation failed, but on further investigation you’ll find that there’s a crack. And some of the programs that we do, leak testing and vacuum impregnation, if it leaks in an area that we know is prone to cracking, the casting will get scrapped and not even impregnated.

So, I hope this information is helpful. If you have any questions, please look me up on LinkedIn or hit me up on WhatsApp and be happy to help out more. Take care and bye for now.