Productivity and quality are keys to the success of any continuous flow production philosophy. However, vacuum impregnation systems have remained antiquated, which causes production and quality issues in modern manufacturing environments. Hence their absence from most continuous flow production plans.Such is the case of a vertically integrated automotive OEM. This company had an outdated vacuum impregnation system that did not meet their continuous flow strategy. The division that operates the vacuum impregnation system pours the metal, machines, and assembles components to produce finished engines.

The Challenge

At the launch of a new engine block line, the company realized that its current vacuum impregnation system could not reliably process the new engine blocks. The OEM realized that the following challenges needed answered:

- Sealing Rate-The system was Dry Vacuum (DV) process only that resulted in below-average sealing rates.

- Floor space– The current automated system was enormous. It did not fit the desired floor space or integrate with production. As a result, the size was debilitating to their production flow.

- Maintenance– The system required continuous support. Maintenance areas were difficult to access. Spare parts were expensive and needed the company to keep a high inventory.

The Solution

The OEM’s leaders realized that the current vacuum impregnation system would need to be replaced with a modern impregnation system.

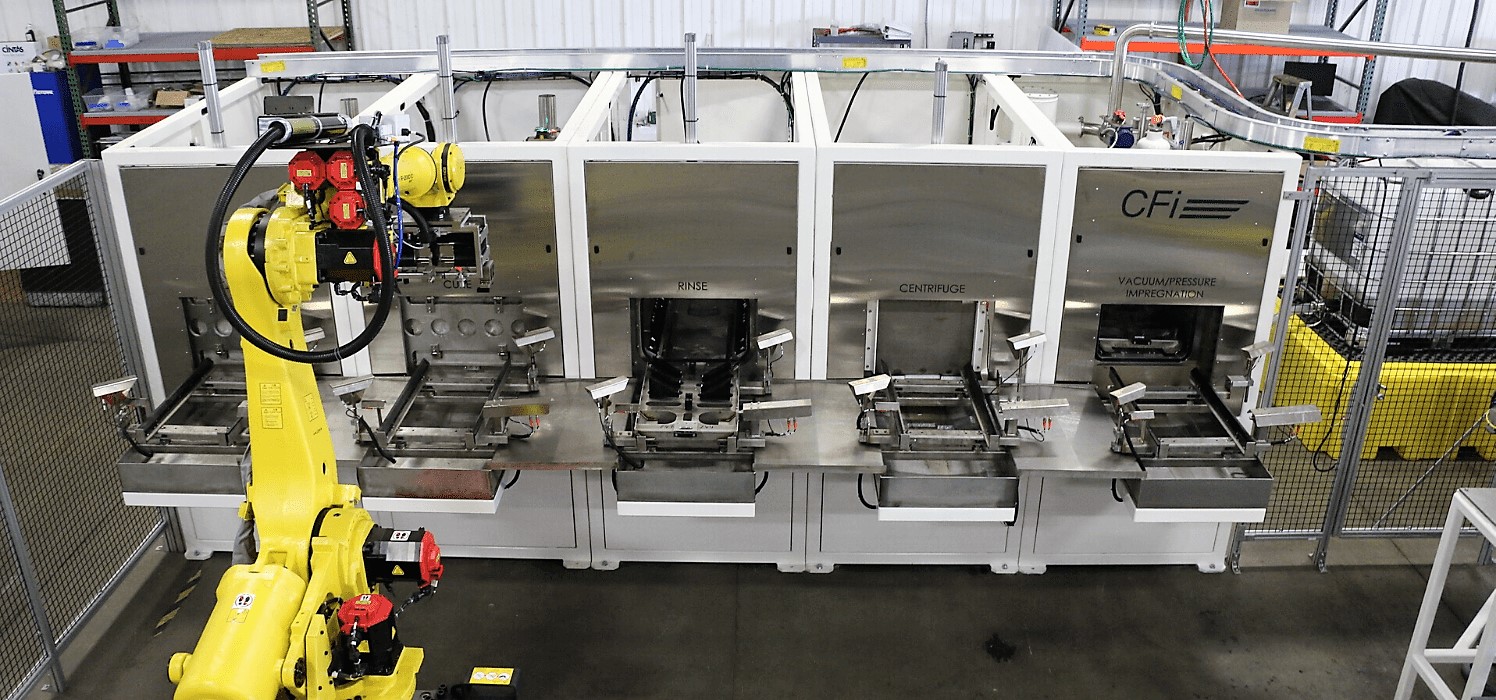

Based upon these roadblocks, Godfrey & Wing recommended its Continuous Flow Impregnation (CFi) system. The system would be customized to answer the customer’s challenges.

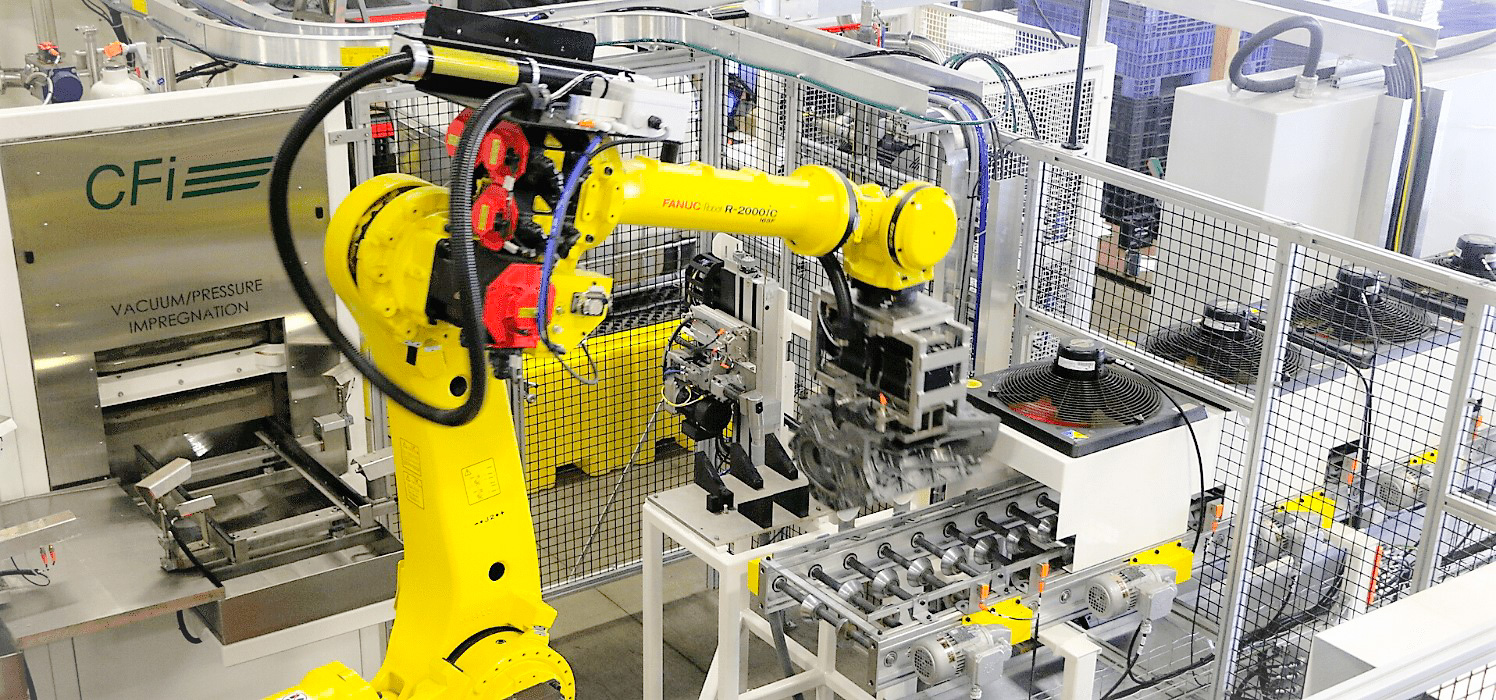

To improve the sealing rate, the CFi uses the patented Dry Vacuum and Pressure (DVP) process, which yields a higher seal rate than the DV process. The CFi with the DVP process incorporates a fast, deep vacuum to evacuate the air from the porosity. Then after moving sealant to the part, the system applies high pressure to allow the sealant to penetrate deep in the casting walls.

The OEM specified precisely where to place the system on the manufacturing floor. Knowing this, the Godfrey & Wing engineering team designed the layout to accommodate the floor space and production integration.

The system was designed with a 7-axis robot for parts handling, and conveyors integrated with machining and leak test operations. The robotic arm forms the interface between the impregnation system and the processing line while using the least amount of space. After impregnation, the castings are fed by the robot directly to leak testing via a cooling conveyor belt. The automation enables continuous production in a modular, compact space.

The internal components were positioned to enable ease of maintenance without interrupting production. The maintenance team is now able to service principal components through the rear panel doors, rather than accessing the system through the safety fence. Sanitary connectors are used that can be maintained by hand without the need for specialty tools. Each module has a line rate disconnect so that maintenance does not need to power down the entire system for service.

The Results

The CFi was installed, operators and maintenance were trained, and the system was running production in two months. Since then, the CFi is addressing all the company’s challenges.

- Increased Sealing Rate– The CFi has increased recovery of the castings by 15%. Scrap from porosity has been virtually eradicated.

- Conserve Floor Space– The system layout cut required floor space by over 50%.

- Reduced Maintenance Cost– The purchase of the CFi has reduced maintenance costs by 65%.

In Summary

As OEMs search for ways to improve continuous flow manufacturing, it is necessary for a paradigm shift. This OEM found value in doing so by investing in a lean and modern vacuum impregnation system. The CFi plays an integral production role by increasing casting recovery while reducing maintenance