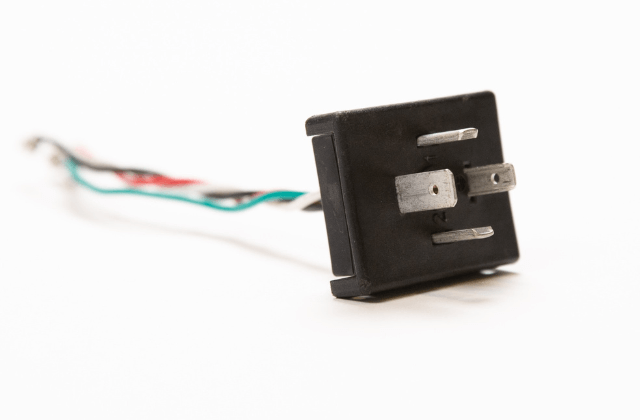

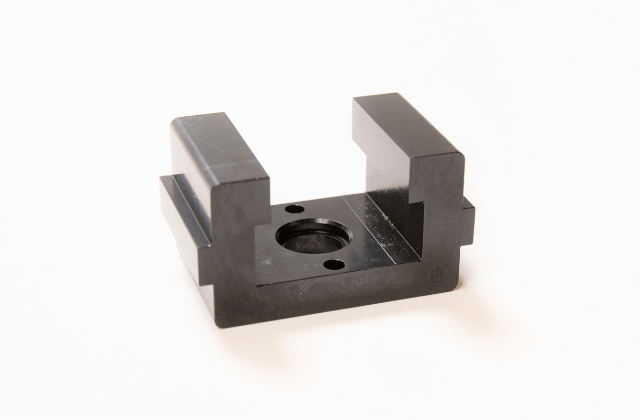

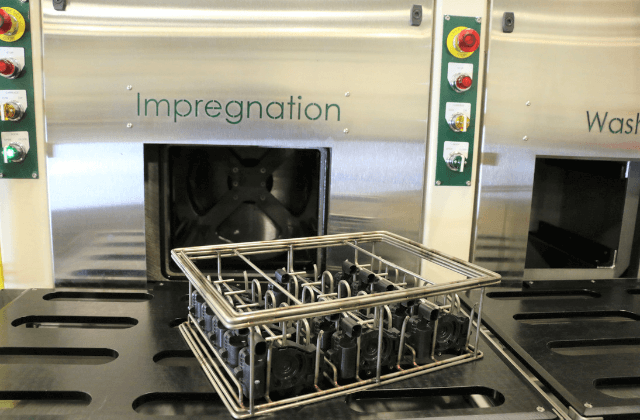

Anaerobic sealants are commonly used for powdered metal 3D printing, and overmolded electrical components. Because they cure at room temperature with no heat, they’re ideal for impregnating components with dissimilar materials that have varying coefficients of thermal expansion. These sealants are optimal for the Wet Vacuum (WV) process.

| 95-1000AC | 95-1000ACP | Elecflex 440 | Elecflex 330 | ElecflexFP | |

|---|---|---|---|---|---|

| General Purpose | Castings | Powder Metal | Electronics | Fuel delivery components | Flame resistant |

| Hardness, Shore D | 79 | 83 | 52 | 70 | 50 |

| Density | 1.21 gms/cc @ 72°F (22°C) | 1.22 gms/cc @ 72°F (22°C) | 1.06 gms/cc @ 72°F (22°C) | n/a | n/a |

| Coefficient of Thermal Expansion | 2.5 x10-4 in/in/in °C | 2.8 x10-4 in/in/in °C | 1.52x10-4 in/in/in °C | 2.5 x10-4 in/in/in °C | n/a |

| Compressive Strength | 9,668 psi | 10,275 psi | 3,339 psi | n/a | n/a |

| Compressive Modulus | 38,672 psi | 146,786 psi | 5,757 psi | n/a | n/a |

| Operating Temperature | -40°F to 401°F (-40°C to 205°C) | -40°F to 401°F (-40°C to 205°C) | n/a | n/a | -51°F to 401°F (-46°C to 205°C) |