Die casting is a metal casting process that injects molten metal through high pressure into a die. It is an economical process that can manufacture a high volume of parts. While die castings have a good surface finish and are dimensionally accurate, porosity inside the part is inevitable.

This blog will define die casting porosity, problems porosity causes, and how vacuum impregnation seals die casting porosity.

What is Die Casting Porosity?

Porosity is any void or hole found within the casting. Porosity is inherent in die casting manufacturing. While economical, the high-speed process of injecting molten metal into a die inherently creates porosity. The two most common types of casting porosity types are: gas porosity and shrinkage porosity.

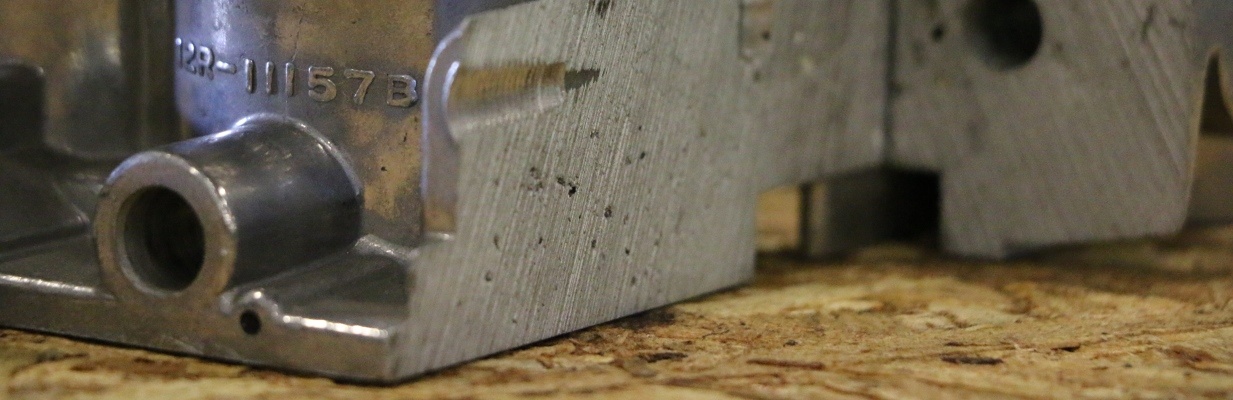

Gas porosity is trapped air in the casting. Gas porosity looks like bubbles with a smooth interior. Gas porosity is always buoyant and will be near the top of the casting (Figure 1).

Figure 1: Gas porosity looks like bubbles with a smooth interior.

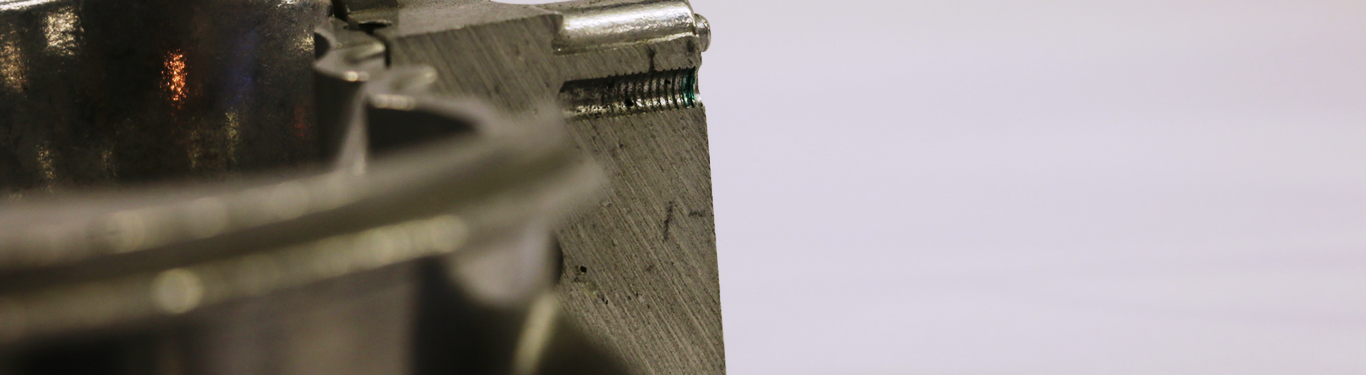

Shrink porosity is internal cracks in the casting. Shrink porosity has a jagged or linear appearance. Shrinkage porosity usually occurs in either the cope or drag portion of the casting and below the surface (Figure 2).

Figure 2: Shrink porosity has a jagged or linear appearance.

Why is Porosity a Problem?

While porosity is inherent in die casting manufacturing, its presence may lead to component failure where pressure integrity is a critical characteristic. Porosity may take on one of the following forms:

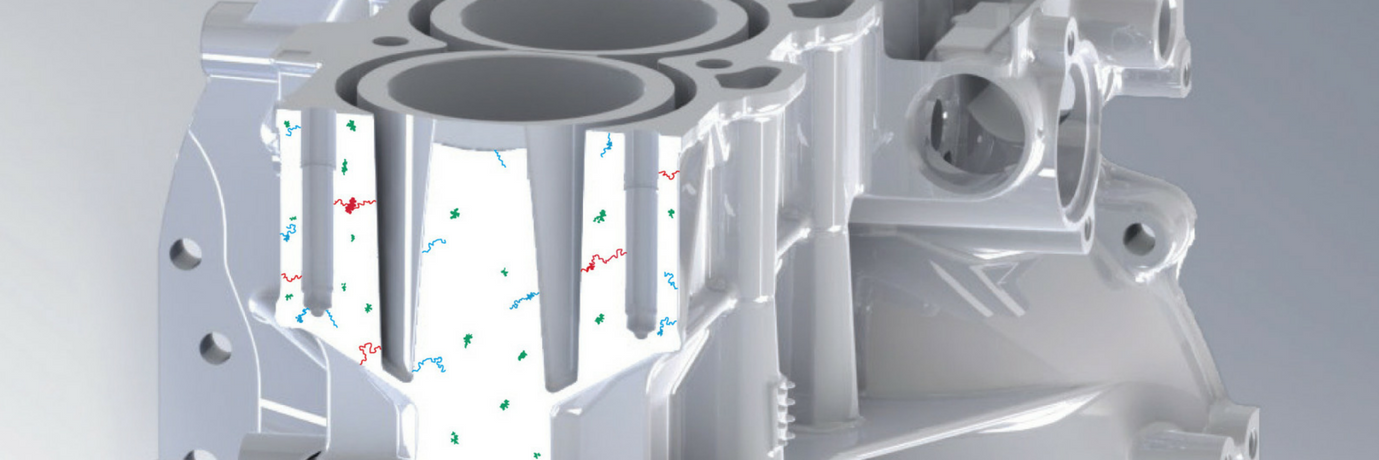

- Blind Porosity(highlighted in blue): From one surface only and therefore not forming a continuous passage for liquid.

- Through Porosity(highlighted in red): Stretching from one side of a casting to another thereby causing a leak path.

- Fully Enclosed Porosity (highlighted in green): Enclosed within the casting, and has no passage to the surface.

Blind and Through Porosity cause immediate casting problems. Blind Porosity can cause internal corrosion. Blind Porosity can cause defects on the part surface when secondary treatments, like powder coating or anodizing, are done. This is because solutions used to clean the castings before the treatment will leech out of the voids after the surface finish process.

Through Porosity will affect the part’s structural integrity, creating a failure point. Through Porosity will prevent the part from being pressure tight. This will impact performance if the part is designed to hold gases or fluids.

Fully enclosed Porosity is not a problem unless secondary machining uncovers this porosity. Machining can break Fully Enclosed Porosity, which will then turn it to either Blind or Through Porosity.

Related: Should Porosity Be Sealed Before or After Machining?

How to Fix Die Casting Porosity?

Vacuum impregnation is a method that seals the casting resulting from porosity. The impregnating material is introduced into the voids within the casting wall thickness through the vacuum and pressure methods. This method is a cost-effective and permanent solution to casting Porosity. There is no limit to the size of castings that can be impregnated.

A key characteristic of a successful impregnation process is that it seals the component without changing its assembly, functional or physical characteristics. Assembly characteristics include tapped holes, the integrity of mating and sealing surfaces, and the elimination of residual contamination. Functional characteristics include the ability for fluids or gasses to flow only where needed. Physical characteristics are that the component must not appear to be different in any manner.