Godfrey & Wing has received a contract from a multinational powersport manufacturer to supply a Continuous Advanced Powertrain (CAPi) vacuum impregnation system. In 2022, the CAPi system will seal leak paths in aluminum die castings for lawn, garden, and industrial products. The system will be installed in the company’s Missouri facility.

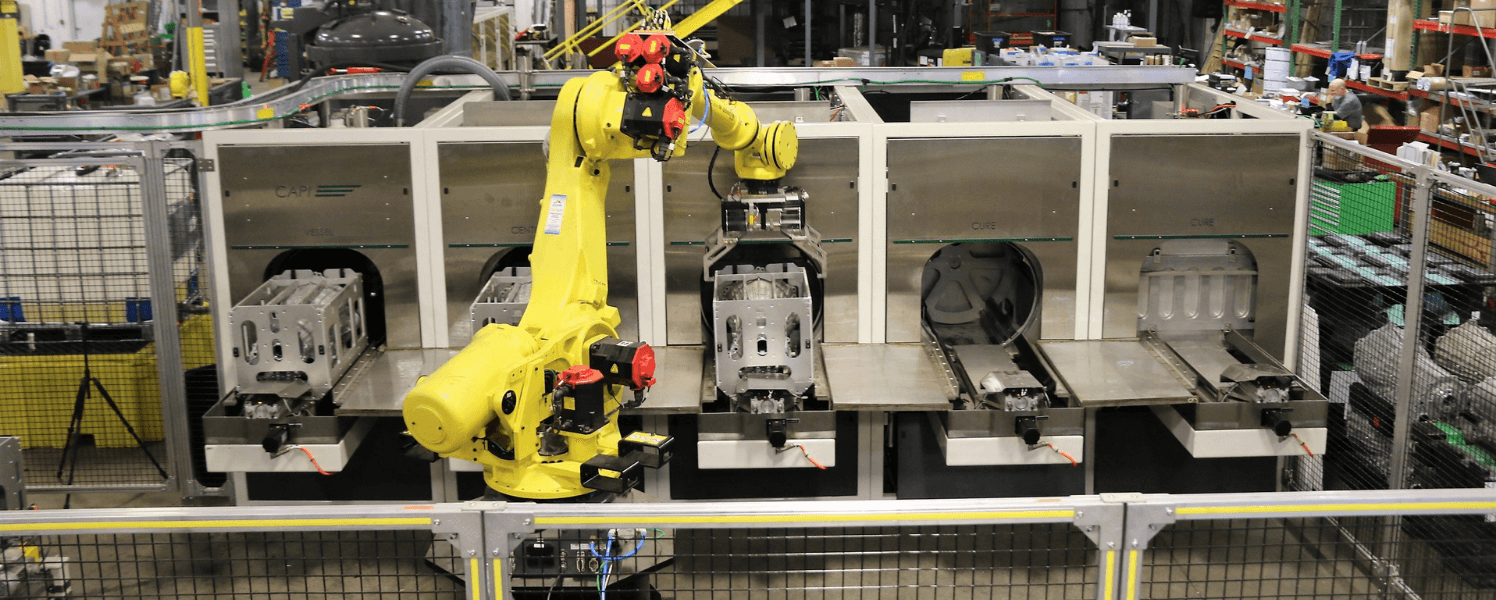

The CAPi is an automated single-piece flow impregnation unit incorporating Godfrey & Wing’s patented Dry Vacuum & Pressure (DVP) impregnation process. The system includes the most advanced porosity sealing technology and a seven-axis ABB robot that tends the system.

The need for the CAPi is a result of increased product demand. The CAPi’s automation will seal porosity at a higher rate in a shorter cycle time with minimal labor. In addition, the CAPi will integrate with the customer’s production. This production integration allows for single part flow throughout the manufacturing process.

The CAPi will meet the current demand and will scale to meet expected higher volumes. Since 2018, this is the company’s second system purchased from Godfrey & Wing. Considering the manufacturer’s demands, Godfrey & Wing technology has proved to be the best solution.

“This CAPi will play an integral role in manufacturing these parts.”Said Dan Irvin, North American Business Development Manager,“This system is the best solution to meet production demand while ensuring part quality.”