Godfrey & Wing announces the introduction of its single-point impregnation process. Developed to make electric vehicle (EV) battery pack assemblies safer and more reliable, this patent-pending process seals porous leak paths that form naturally in metal castings used in these battery assemblies.

This process is applicable in a completed assembly or can be used for individual castings prior to assembly. Sealing these leak paths helps prevent coolant leakage, avoiding defects, recalls, and possible failures. Godfrey & Wing is the leading global provider of vacuum impregnation services, equipment, and sealants for the global automotive, aerospace, defense, medical, and general industrial industries.

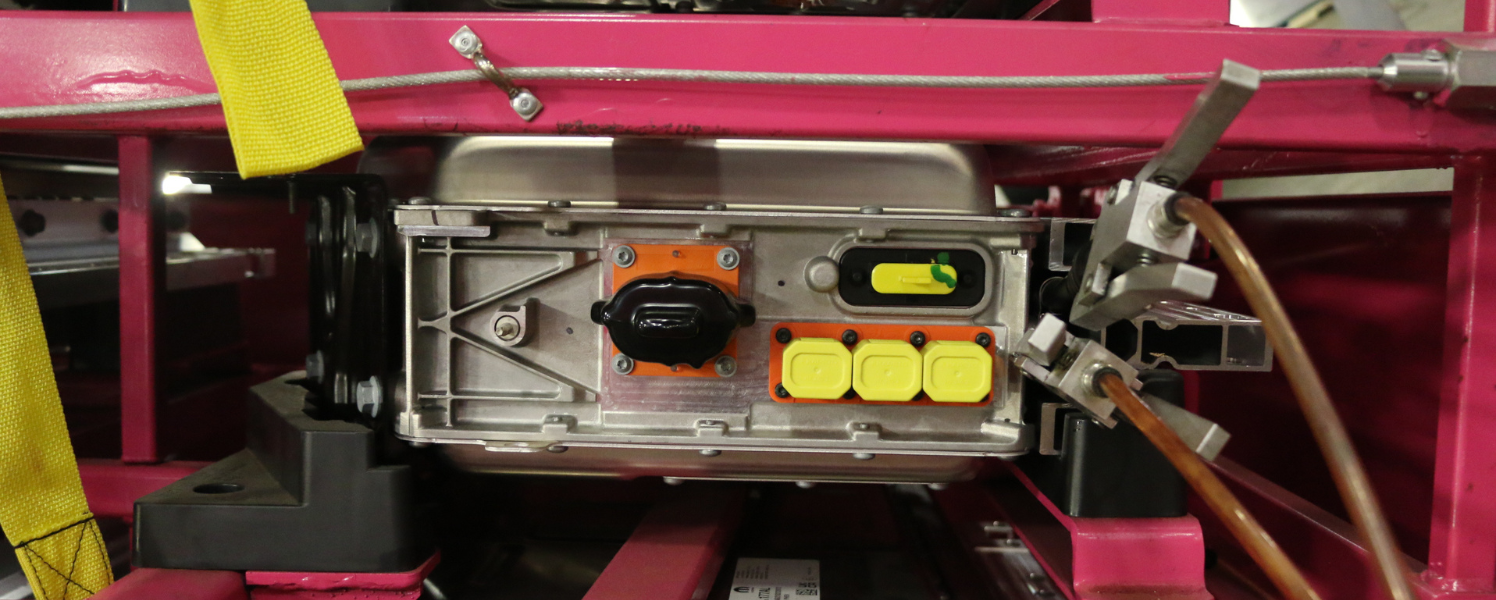

Single-point impregnation eliminates the rigors of traditional vacuum impregnation. Only the leak path is subjected to the process, while the other components are untouched. The process ensures the leak path is sealed with no risk of contamination or damage. This makes the process ideal for fully assembled EV batteries, which contain delicate parts and electronics.

“As the automotive industry evolves quickly to meet consumer demand for EVs, it needs new, proven, and effective manufacturing processes,” says Alexander Alford, CEO. “The development of single-point impregnation is just the latest chapter in Godfrey & Wing’s rich history of customer- and industry-focused innovation. This groundbreaking method of impregnation will help the industry move more swiftly toward an electrified future.”

The EV battery market is expected to grow at 19.9% CAGR between 2022 and 2027, according to Markets and Markets. But as demand accelerates, manufacturers are continuing to search for solutions to a range of engineering challenges.