APi Impregnation System

Godfrey & Wing’s APi allows powertrain manufacturers to have the benefits of vacuum impregnation in a simple, easy to use machine.

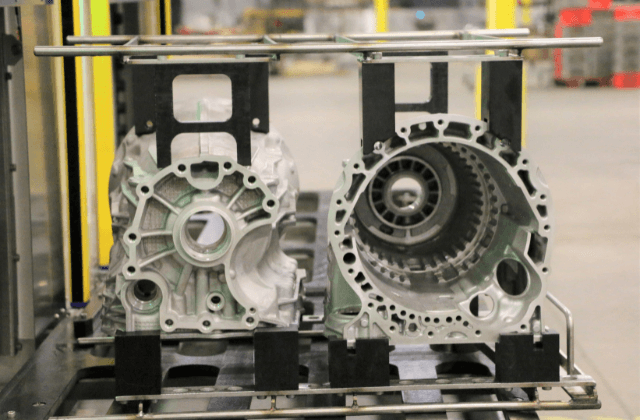

The system efficiently and effectively seals porosity while eliminating the costs and risk of outsourcing. It features a 43% larger work envelope than the HVLV to accommodate large, complex die castings.

Modular Design

The compact design needs only 112 square feet of space. With single point connections for electricity, water and air, and no infrastructure changes needed, the APi can be installed anywhere on the manufacturing floor.

Maximum Recovery, Minimum Effort

The APi contains Dry Vacuum and Pressure (DVP) impregnation chamber. This seals porosity with a first time through (FTT) recovery rate of more than 99%.

Processing 15 cycles per hour makes it the fastest manually operated systems available on the market.

Ensure Part Quality

Continuous flow technology and fixturing ensure porosity sealing and protect critical surfaces. This eliminates handling damage and sealant contamination.

PLC controls ensure the process is repeatable without operator input.

Push the button and the APi does the work.

Operator Safety

Safety is #1. Designed with an ergonomic man-machine interface, the APi keeps the operator and maintenance associates safe and productive.