| 95-1000AA | 95-1000A | |

| General Purpose | Castings, Graphite | Castings, Graphite |

| Hardness, Shore D | 70 | 65 |

| Density | 1.17 gms/cc @ 72°F (22°C) | 1.22 gms/cc @ 72°F (22°C) |

| Coefficient of Thermal Expansion | 4.3 x10-4 in/in/°C | 3.2 x10-4 in/in/°C |

| Compressive Strength | 8,467 psi | 3,759 psi |

| Compressive Modulus | 13,880 psi | 6,265 psi |

| Operating Temperature | -40°F to 401°F (-40°C to 205°C) | -51°F to 401°F (-46°C to 205°C) |

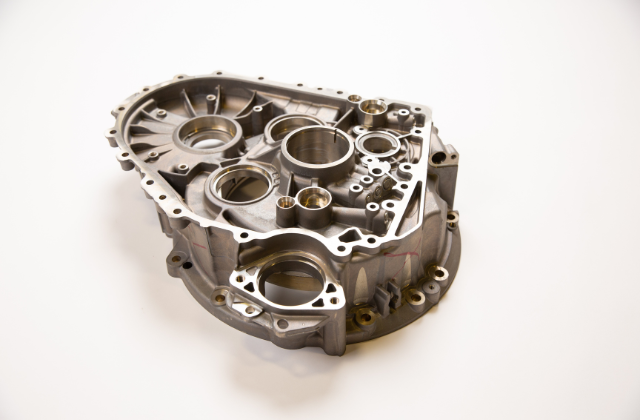

Unrivaled Sealing Performance

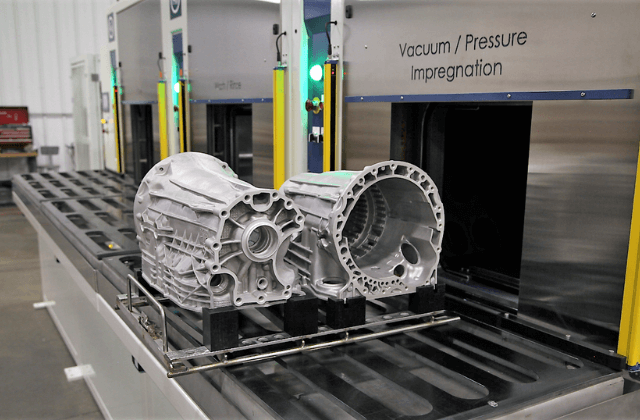

Thermal-cure sealants are commonly used to seal micro-porosity in castings. They cure quickly when heated to 195° F (90°C), allowing parts to be pressure-tested in either continuous-flow or transfer-line type applications.

These sealants are also optimal for the Dry Vacuum and Pressure (DVP) impregnation process.

Approved by OEMs Worldwide

Godfrey & Wing’s thermal-cure sealants are approved by OEMs worldwide. The world’s leading manufacturers trust that Godfrey & Wing’s sealants are repeatable and sustainable.