| Process Used | Internal Pressure |

| Sealant Used | Anaerobic |

| Process Specification | MIL-STD-276A, Method A |

| Sealant Specification | MIL-I-17563C |

Accelerating Solutions in Electric Vehicles

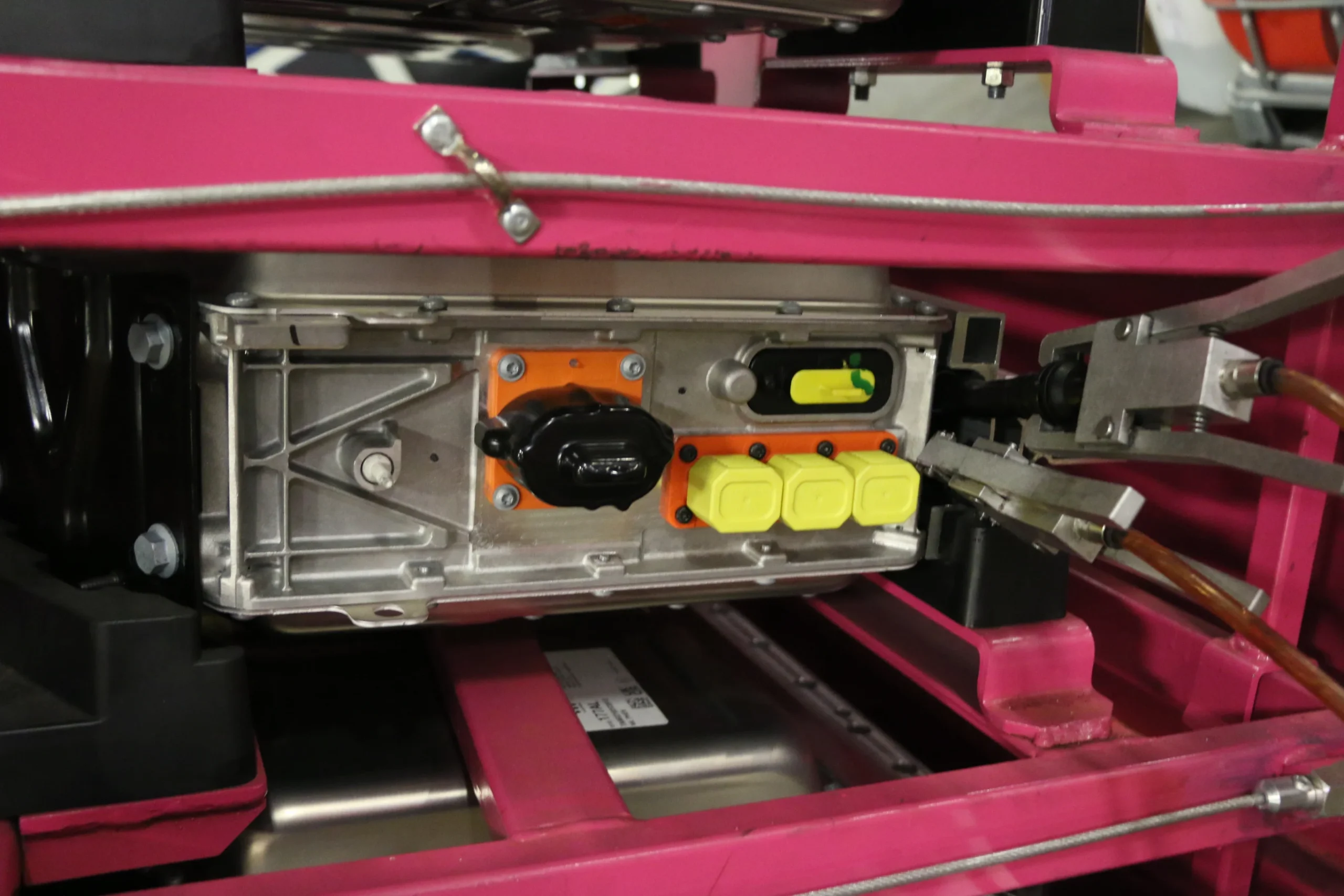

Trusted by automotive OEMs and their suppliers, Godfrey & Wing helps solves the industry’s challenges, enabling the next generation of electric vehicle (EV) design and production.

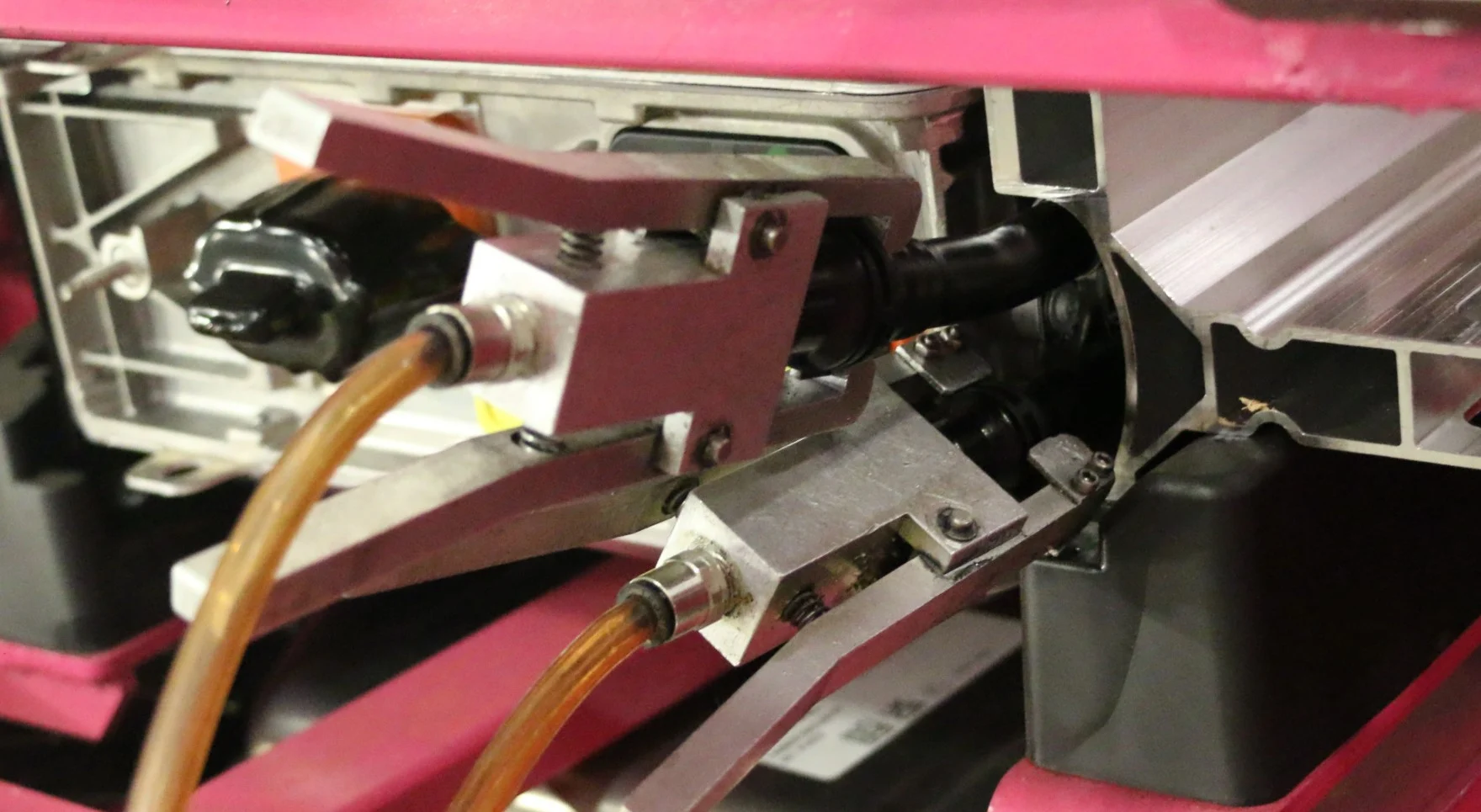

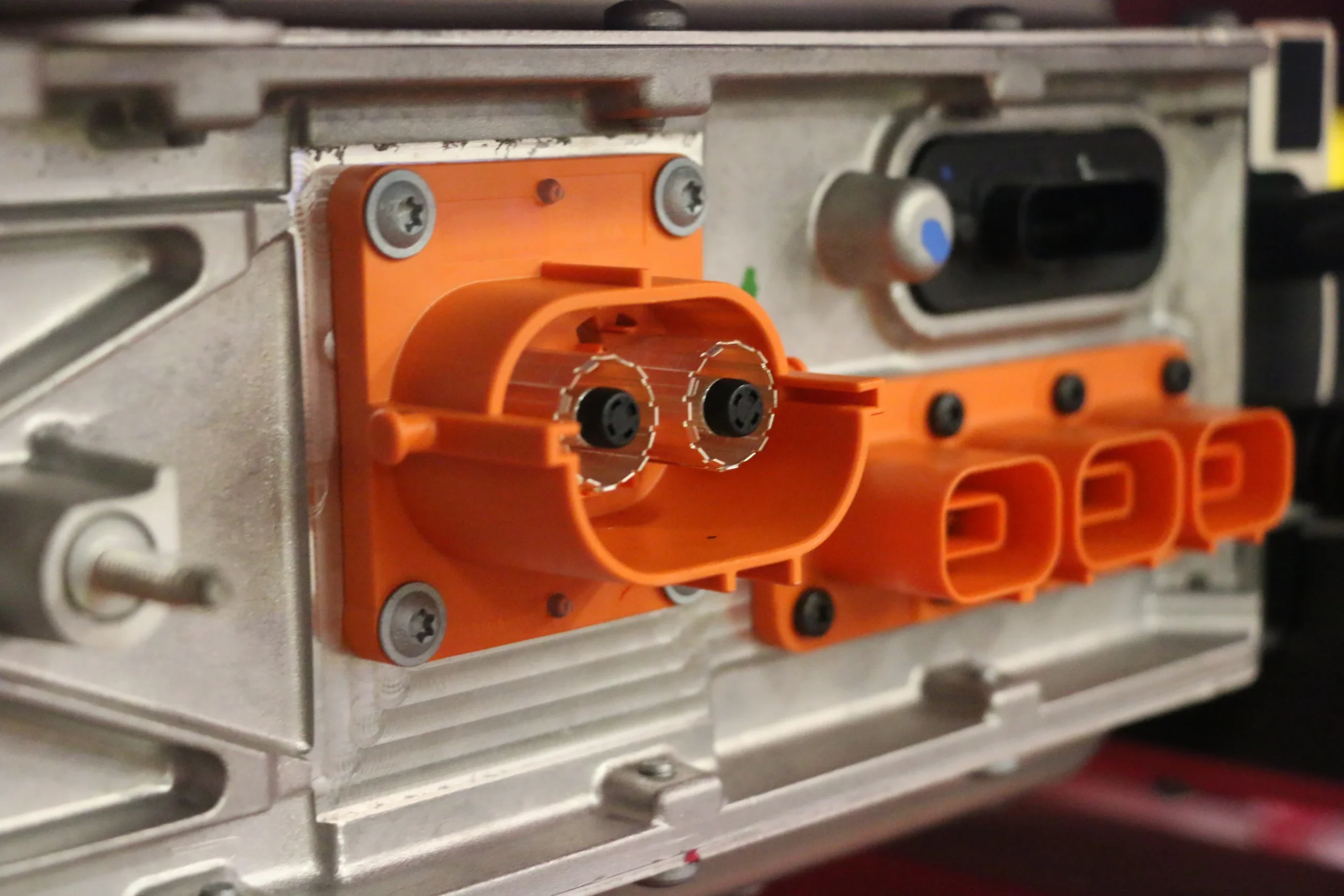

Godfrey & Wing’s patent-pending single-point impregnation seals leak paths in EV battery pack assemblies and drive motor case castings. The process seals completed assemblies or can be used for individual castings prior to assembly.

Sustainability

Godfrey & Wing only uses environmentally friendly sealants. Our sealants are recoverable, meaning they maintain purity without additional chemistry.

Our equipment and processes maximize part recovery while reducing waste. Vacuum impregnation will last the life of the part.