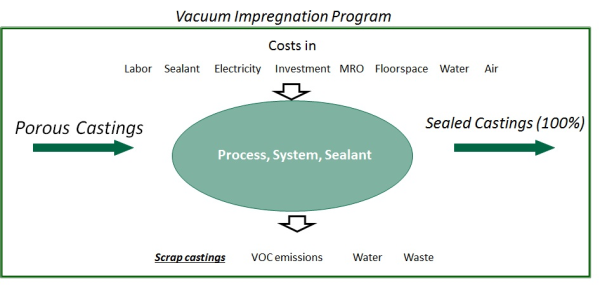

The primary purpose of vacuum impregnation is to seal porous castings and prevent leakage. If the impregnation process is not efficient and fails to seal the casting it will become scrap, and the number and value of these failures will determine the economic viability of the process.

For example, take a machined casting weighing 10 kilograms and with a value of $55. The cost to recover this casting by impregnation is $2, including sealant usage, water usage and energy demand. Successful impregnation will therefore produce a savings of $53 per casting. There is no doubt this is a financially viable process.

However, when comparing different impregnation systems, the “pass rate” becomes the most important part of the financial evaluation. A 10% difference in sealing performance significantly outweighs a 10% saving in processing costs, as shown below.

At a pass rate of 85%: 15 out of 100 castings will be scrapped at a cost of $825.

At a pass rate of 95%: 5 out of 100 castings will be scrapped at a cost of $275.

Therefore achieving a 10% improvement in performance will save $550 per 100 castings.

In comparison, achieving a 10% reduction in the sealant price will only save $8 per 100 castings.

Maximizing the “pass rate” is the key to achieving an economical process.

Therefore, rather than driving down the cost of the process by using lower quality sealants or lower specification equipment, the most effective action is to look at maximizing the sealing performance. The financial savings will be much greater, not to mention higher production output, reduced quality control and better utilization of manpower.

Therefore, rather than driving down the cost of the process by using lower quality sealants or lower specification equipment, the most effective action is to look at maximizing the sealing performance. The financial savings will be much greater, not to mention higher production output, reduced quality control and better utilization of manpower.

Godfrey & Wing can prove that through the development of new technology their impregnation systems can consistently achieve a pass rate of >99% on high volume automotive engine components. This far exceeds the 80-90% success rate that has become an accepted norm in many areas of the industry.

For more details, please contact us online or by calling 330.562.1440.