One of the largest aluminum casting facilities in United States produces engine blocks and transmission cases for an automotive OEM. This facility supplies the vast majority of powertrain castings in support of the OEM’s assembly operation throughout North America.

The Challenge

The casting standards and aluminum characteristics forced the need for vacuum impregnation. The program was launched with a vendor that utilized a Dry Vacuum (DV) process in an older batch style vacuum impregnation system. Unfortunately, the system and process could not meet the quality demands of the foundry or the OEM.

The main challenges were:

- Poor recovery- 14% of the parts still leaked after impregnation.

- Contamination- Cured (solid) sealant remained in through and blind tapped holes.

- Part Damage- Damage to machined features from handling and the impregnation process.

These challenges caused missed shipments, quality alerts and increased rework costs. A better process was needed to deliver a higher quality parts.

The Solution

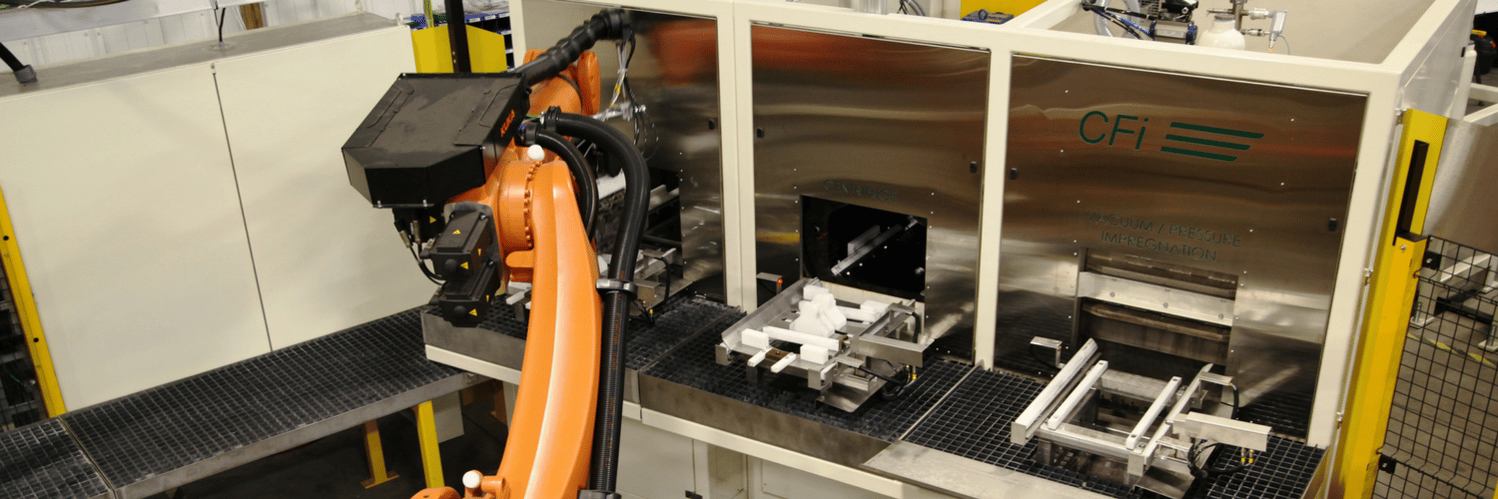

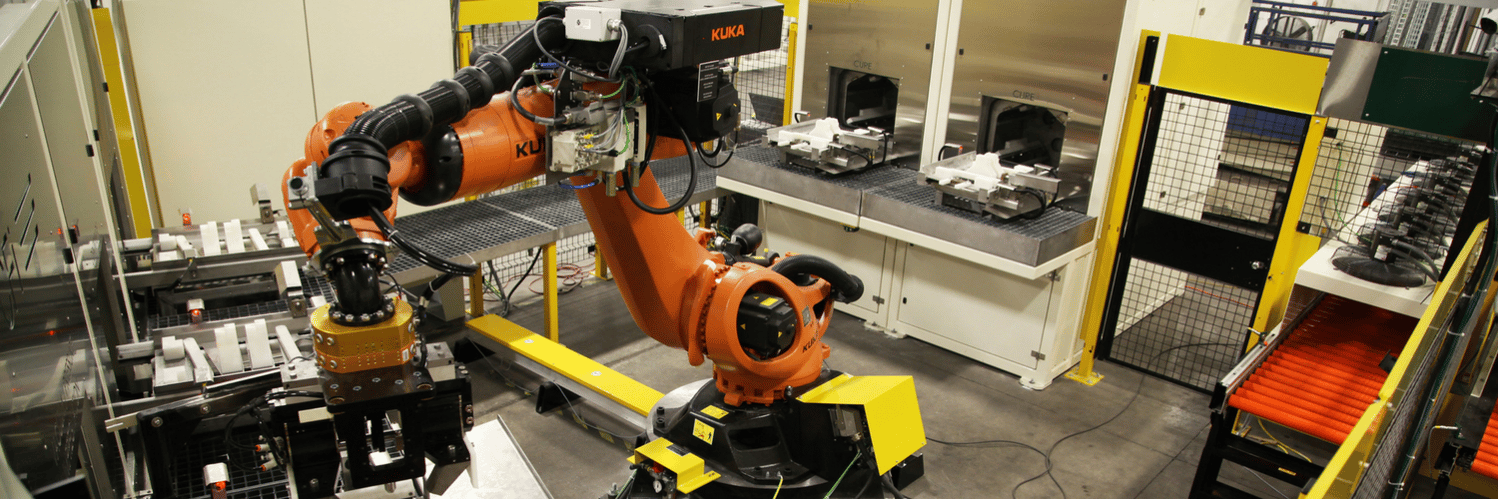

Based on the customer’s requirements and production quantities, Godfrey & Wing proposed the Dry Vacuum and Pressure (DVP) Continuous Flow vacuum impregnation (CFI) process for the customer’s parts. The CFi seals high volumes of parts in a short cycle time with minimal labor. The system uses a recoverable sealant, maintaining the sealant in is original and purest state, which allows for repeated use.

Godfrey & Wing’s solution was designed to address each of the customers concerns:

- Dry Vacuum and Pressure (DVP) process- Godfrey & Wing’s data indicated a meaningful improvement in recovery would be found using the DVP process. The previous vendor used a vacuum only process.

- Single fixture part flow- Using single part flow systems allows parts to be fixture in a manner that promotes repeatability and consistent processing. The previous impregnation vendor stacked parts side by side in a random manner in large steel baskets leading to multiple failure modes.

- Automation- Material handling would be done with a robot instead of manual labor. This insures all parts are processed correctly and in sequence. The previous vendor’s batch system is manually controlled where the large baskets could be packed or processed incorrectly.

Having never qualified the DVP process, the customer ran a sample to determine how much more effective it would perform compared to

its existing DV process. The results clearly showed the DVP process surpassed the existing sealing results:

- 100% part recovery- The customer’s part recovery rate increased to 100% with the DVP. This was a 14% improvement over the

average rate with their existing process. - 0% part contamination- Using the DVP process, the customer’s rate of part contamination dropped to virtually zero.

- 0% part damage- The customer experienced no part damage with the DVP process.

Impressed with the results, the customer moved production to Godfrey & Wing.

The Results

During the first year of production, the CFI impregnated over 16,000 parts. The First Time Through (FTT) rate remained at 100% without any contamination or damage. The impregnation process continues to achieve 100% recovery without any contamination or damage. The process seals the parts at 150 cc.

Godfrey & Wing’s CFi with the DVP process solution answered the following challenges:

- Improve Recovery-The DVP process pushes the sealant deep into the micro porosity, which delivers near 100% recovery in a single cycle. The process thus delivers improved sealing efficiency.

- Eliminate Contamination-Instead of packing the parts in a basket; the parts are placed in fixtures that hold either one or two parts. This allows excess sealant is effectively washed from the part during the cycle.

- Eliminate Part Damage-The CFI system is fully robotic; the attendant interacts with the system through the HMI panel. The system’s robotic arm moves the castings between stations, which allows for a shorter cycle time and eliminates operator errors.

In Summary

As companies continue their search for ways to reduce costs and increase quality, it will be necessary to challenge the status quo. This company realized that the DV recovery rates were no longer valid for today. With Godfrey & Wing’s technology and processes, this company maximized casting recovery, reduced costs and improved quality.